- Technical specifications

- Real benefits for large retailers and logistics hubs

- Design features of the FFR.15 roll container

- Cargo security thanks to a special door locking system

- Order form for roll container FFR.15

We can produce roll containers with different wheel diameters to order. If you need a roll container with three walls and a door and several shelves, look for modular containers. This model does not include additional shelves.

Photo No. 2 in the gallery shows the principle of folding and “rolling” roll containers: the next one into the previous one when storing them in an unused state.

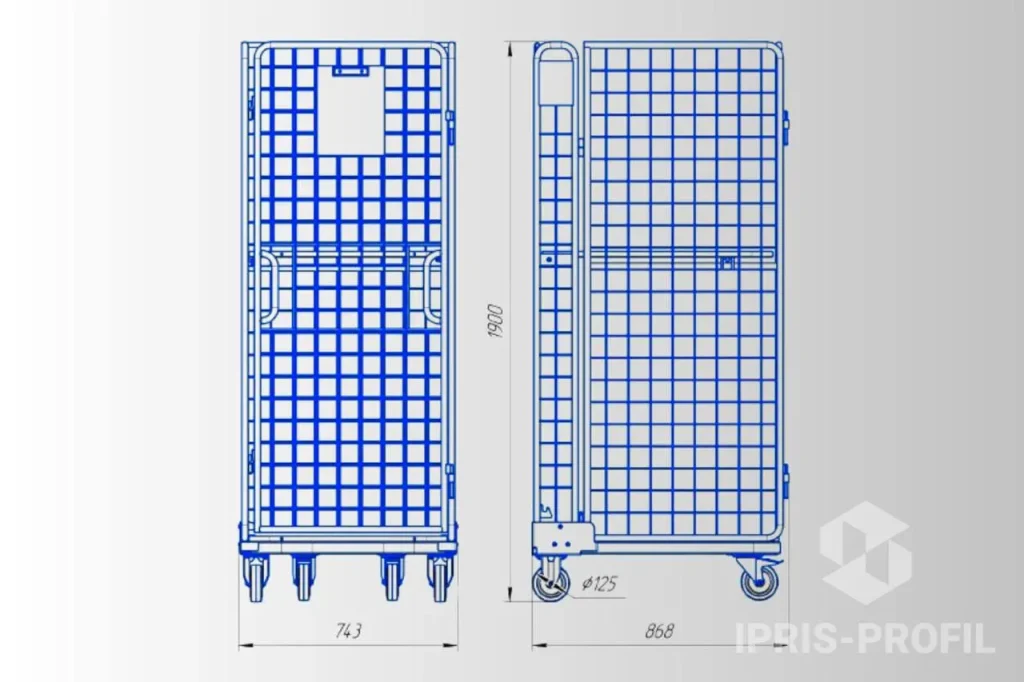

TECHNICAL SPECIFICATIONS OF THE FFR.15 ROLL CONTAINER

| Size: | 743 x 868 x 1900 mm | |

| Load capacity | 550 kg | |

Shelf load: | up to 120 kg | |

| Mesh size: | 75 x 75 mm | |

| Wheel diameter: | 125 mm | |

| Coating: | Powder coating/galvanising |

Key Operational Advantages of FFR.15 Nestable Roll Containers (based on the experience of leading European retailers and logistics hubs)

While most manufacturers focus solely on space-saving, the FFR.15 nestable roll container design provides unique strategic benefits that are critical for high-intensity supply chains:

1. Loading Dock Throughput (Optimization of the “Bottleneck”)

In logistics, the real bottleneck isn’t the road—it’s the time a vehicle spends at the loading bay.

- The Problem: Traditional pallet loading is discrete and machine-dependent. The ramp “waits” while a forklift picks up a pallet, drives in, unloads, and drives back out.

- The FFR.15 Solution: Roll cages enable continuous parallel loading. In the same footprint where one forklift handles one pallet, three employees can simultaneously load multiple roll containers.

- The Result: Vehicles clear the loading dock 15–20 minutes faster. Goods move seamlessly from the truck directly to the store shelf (Dock-to-Shelf). For a warehouse with 50 gates, this allows for several additional truck rotations per day without physical expansion.

2. Deployment Speed & Asset Integrity

Lost side panels and broken shelves are a major hidden cost for modular or demountable cages.

- The Problem: Preparing demountable roll containers for use or storage is labor-intensive. Workers must remove panels, stack bases, and secure loose parts—taking minutes per unit and requiring extra floor space for components.

- The FFR.15 Solution: The FFR.15 features a monobloc nestable construction. There are no removable parts to lose at the ramp or leave behind in the retail store. Units are nested into each other in seconds.

- The Result: A drastic reduction in repair and replacement costs. You always have ready-to-work equipment on hand, rather than a pile of mismatched parts that cannot be assembled into a functional unit.

3. Dynamic Buffer Management

Cross-docking terminals often face “waves” of incoming empty equipment that can paralyze the loading zone.

- The Problem: Disassembled modular cages are “dead weight.” They cannot be moved quickly as a group, creating obstacles in the receiving area.

- The FFR.15 Solution: Nestable containers, collected in a “line” of 10–15 units, transform into a highly manageable train. A single operator can easily push a line of nested cages to the other end of the warehouse.

- The Result: Superior warehouse maneuverability. You can clear the docking zone instantly by moving lines of empty containers — just like supermarket trolleys — keeping your transit areas clear and productive.

Key parameters of the FFR.15 Nestable Roll Container

| Cargo security | Four-sided mesh protection and doors prevent contents from falling and being damaged during transport. |

| Nestable design | Up to 70% space savings when storing empty mobile containers (compared to modular roll containers). |

| High load capacity | Maximum container load capacity: 550 kg. Shelf load capacity: up to 120 kg. |

| Reliable door locking | Door locking system without straps or latches, which speeds up the loading process. |

| Environmental friendliness and cost savings | Made of steel, the roll container is a reusable alternative to disposable packaging (cardboard/film), reducing operating costs. |

Space optimisation and convenience thanks to nestable design

Thanks to its nestable design, the roll container optimises space utilisation. When mesh containers on wheels are not in use, they can be rolled into each other (as shown in Photo No. 2), which significantly reduces the space required for storage and simplifies manoeuvring empty containers. Empty roll containers take up almost 80% less storage space compared to when they are in use.

Speed and reliability of door locking

The FFR.15 roll container design features a door locking system that does not require additional devices such as straps or latches. To close/open the door, simply lift it slightly using the two ergonomic handles.

This design of roll containers on wheels allows you to send the goods in the container to the loading area of the vehicle even faster and not worry about the door opening spontaneously.

Cargo security and integrity

Unlike open pallets, FFR.15 roll containers are equipped with mesh side walls and a door that prevent the contents from falling or being damaged during transport, which is particularly important when handling fragile or expensive goods.

Economic and environmental benefits of using the FFR.15 roll container

The roll container is made of steel, making it an environmentally friendly alternative to disposable packaging. Its reusability directly translates into cost savings over time, reducing dependence on cardboard boxes and shrink wrap.

In addition, their long service life and low maintenance requirements make mobile containers on roller wheels a practical investment for any business seeking to reduce operating costs.

Order 4 Sided Roll Container Nestable FFR.15

The 4-sided mesh container on wheels has a sturdy and robust design for the safe transport of goods in the warehouse/enterprise or during transit to the unloading point. Mesh panels on 4 sides provide excellent visibility and ventilation, preventing contents from shifting or falling out. This feature is particularly useful in environments where cargo security and integrity are of paramount importance.

Thanks to its drive-in (nested) design, the roll container optimises the use of space and provides efficient storage options. When not in use, the mesh wheeled containers can be rolled into each other, significantly reducing the storage space required. This design also ensures easy handling and manoeuvring of empty containers, optimising operations and saving time.

Whether you need to transport goods, manage stock in the warehouse or organise deliveries in retail, the 4-sided roll container on wheels is the ideal choice. Its robust construction, versatile design and exceptional functionality make it an indispensable asset for optimising your merchandising operations.

We have 15 models on our website. If you have not found the right one, place an order for the design and production of a batch of roll containers with your own characteristics!

Switching to modern mobile storage solutions not only improves internal logistics, but also increases employee safety, reduces costs and makes operations more sustainable. If your business regularly handles large volumes of goods, it’s time to consider investing in a smarter way to transport and store your goods.