Specifically designed as a plastic containers euro crate trolley, our carts accommodate all standard Euro-format bins (600×400, 400×300 mm).

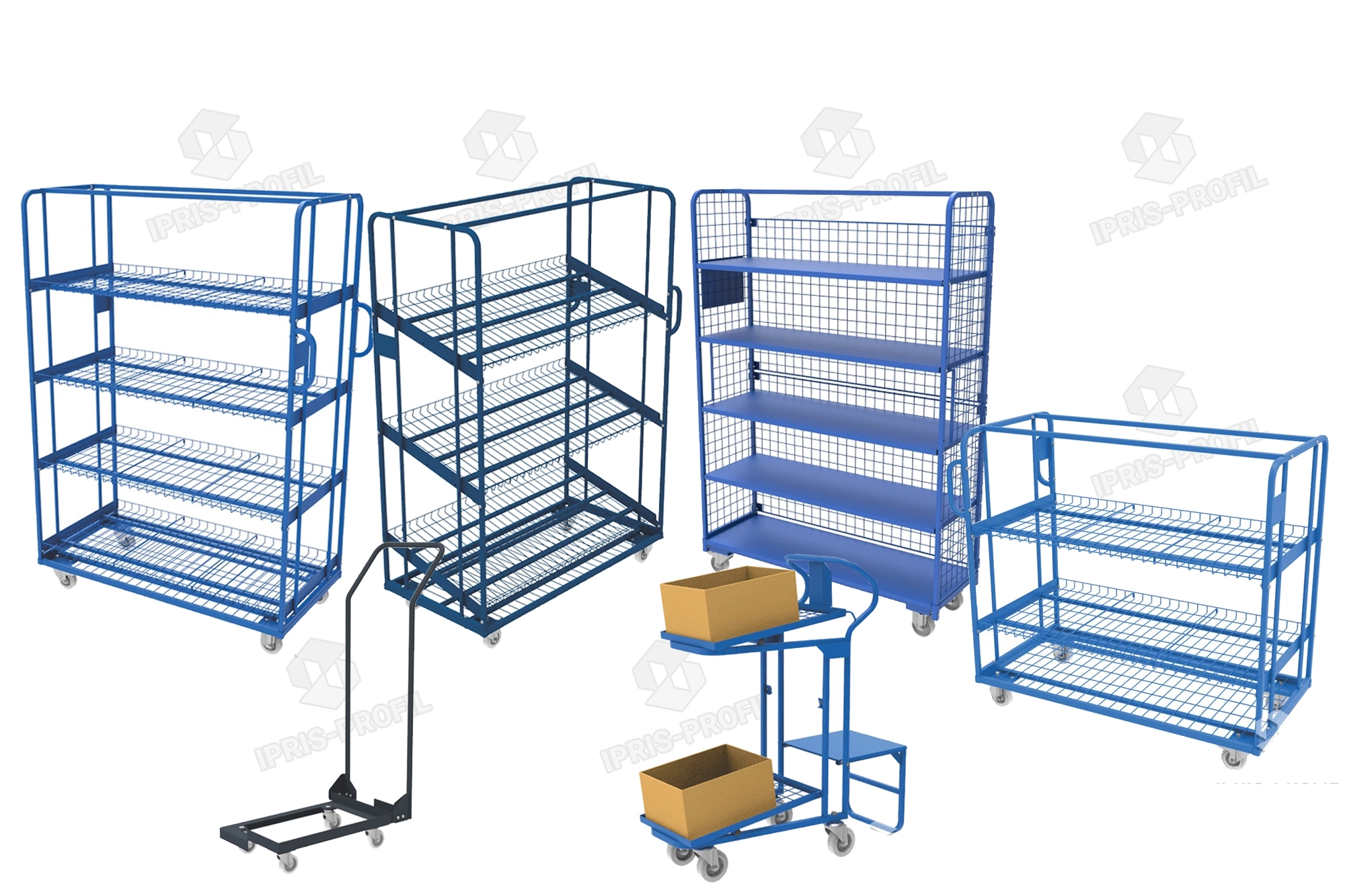

Euro container trolley TDK.02

| Overall dimensions, mm | 1300х650х1225 |

| Load capacity, kg | 200 |

| Load capacity per shelf, kg | 100 |

| Wheel diameter, mm | 100 / 125 |

Trolley for plastic containers 600 x 400 mm TDK.03

| Overall dimensions, mm | 1300х650х1895 |

| Load capacity, kg | 400 |

| Load capacity per shelf, kg | 100 |

| Number of shelves, pcs | 4 |

| Wheel diameter, mm | 100 / 125 |

| Coating | Galvanised/powder coating |

Euro crate trolley TDK.07

| Overall dimensions (WxDxH), mm | 1380х645х1890 |

| Load capacity, kg | 400 |

| Load capacity per shelf, kg | 120 |

| Shelf angle | 15 ᵒ |

| Wheel diameter, mm | 100 / 125 |

| Coating | Порошковое покрытие |

Euro Container Shelf trolley for plastic boxes 400×300 or 400×600 mm

| Overall dimensions, mm | 1246х420х1832 |

| Load capacity, kg | 500 |

| Load capacity per shelf, kg | 100 |

| Wheel diameter, mm | 100 / 125 |

| Coating | powder coating |

Tote box trolleys OZO.01

| Overall dimensions (WxDxH), mm | 870х485х1170 |

| Load on upper shelf, kg | 40 |

| Load on lower shelf, kg | 60 |

| Height of folding step, mm | 390 |

| Wheel diameter, mm | 125 |

| Coating | Polymer powder coating |

Transport trolley for stackable boxes 600 x 400 mm VDK.01

| Overall dimensions, mm | 615х380х1120 |

| Load capacity, kg | 150 |

| Wheel diameter, mm | 75 / 80 |

| Coating | Polymer powder coating |

Where Our Euro Container Trolleys Make a Real Difference

A euro container trolley isn’t just a piece of warehouse furniture; it’s a versatile tool that adapts to whatever business you’re in. We’ve seen our equipment solve problems in some of the busiest environments imaginable.

Manufacturing & Automotive: Keeping the Line Moving

In a busy factory, the last thing you want is a cluttered workstation or a worker walking halfway across the building for a single bolt. Our euro crate trolley is the backbone of the “Milk Run” system. It allows your team to bring exactly what’s needed directly to the assembly line. By keeping components organized in tote box trolleys, you clear up floor space and make sure your experts spend their time building, not searching for parts.

E-commerce & Fulfillment: Error-Free Picking

We know that in E-commerce, speed is everything, but accuracy is what keeps customers coming back. When a picker uses our euro container shelf trolleys, they can sort multiple orders on the go. Instead of one big pile of items, everything stays in its own bin. These euro box carts are light and easy to push, which means your team stays fresh and focused even during the busiest holiday shifts.

Retail & Supermarkets: Restocking Without the Obstacle Course

We’ve all been in a store where a massive pallet blocks the entire aisle—it’s frustrating for customers and staff alike. Our euro container trolley is slim enough to glide past shoppers unnoticed. It’s the perfect partner for restocking shelves. Because they are quiet and easy to steer, your team can get the job done quickly, leaving the aisles clear and the customers happy.

Pharmaceuticals & Labs: Handling with Care

In healthcare and labs, there’s no room for “good enough.” Cleanliness and precision are mandatory. Our euro box transport solutions are built with smooth, powder-coated finishes that are easy to wipe down and keep sterile. These tote box trolleys provide a stable, vibration-free ride for sensitive samples or expensive medications, ensuring everything arrives exactly as it should.

Boosting Your Internal Logistics

Optimization isn’t always about expensive automation; sometimes, it’s about making sure your goods never have to wait. Using a euro container trolley transforms your warehouse from a place where things are “stored” into a place where things “flow.”

- Eliminate “Dead Time”. Instead of moving one box at a time or waiting for a forklift to clear a path, your team can move an entire stack of orders in seconds. Our euro box carts are the perfect bridge between your storage racks and the packing station.

- Pick and Sort in One Go. Why sort items twice? With euro container shelf trolleys, your pickers can sort items directly into the correct bins as they walk. By the time the trolley reaches the shipping zone, the order is already organized and ready for labeling.

- Save Your Floor Space. Huge pallets clutter up aisles and create bottlenecks. Switching to compact tote box trolleys frees up to 20-30% of your usable floor area, giving your team more room to move safely and efficiently.

- A Smoother “Milk Run”. For production lines, these trolleys are the secret to a perfect “Just-in-Time” setup. Swap empty bins for full ones without ever stopping the assembly process.

By integrating the right euro container trolley into your daily routine, you’re not just moving boxes—you’re cutting down travel time, reducing physical strain on your staff, and getting orders out the door faster than ever before.

Custom Solutions by Ipris-Profil

With over 20 years of experience and a specialized R&D bureau, we don’t just provide standard equipment. We can adapt any euro container shelf trolleys or tote box trolleys to your specific height requirements, load capacities, or caster types.

Whether you are looking for a single euro box trolley or equipping a 35,000 sq.m. logistics center, Ipris-Profil delivers the engineering expertise to keep your business moving forward.

The “Before” Situation: Components such as screws, connectors, and housings were stored in large boxes on static racks located directly behind the assembly operator. To assemble a single unit, the technician had to constantly turn around, search for the correct container, and reach back. This created repetitive strain and significantly slowed down the process.

The Solution with Euro Container Trolleys: We implemented mobile euro container shelf trolleys featuring angled shelves designed for 400×300 mm bins. Each trolley is organized as a complete “kitting station” containing all the parts required to assemble 20 units. The trolley is positioned at an angle directly in front of the operator, within their natural reach zone.

The Result: Optimization through Ergonomics and Order

- Cycle Time Reduction: Assembly time was cut by 15%. Because the bins are tilted and positioned directly in front of the worker, every movement follows the shortest possible path (the “Golden Zone” of ergonomics).

- Lower Defect Rate: Error rates dropped significantly because each trolley contains only the specific components required for the current model. This eliminates the risk of a “wrong part” error, such as picking a similar-looking bolt from a neighboring bulk box.

- Streamlined Logistics Flow: The replenishment process was transformed. Instead of a warehouse worker walking through the shop floor to refill individual boxes, they now simply swap an empty euro box trolley for a fully pre-kitted one.

Order a trolley for 400×600 mm boxes at the best price directly from the manufacturer, IPRIS-PROFIL Ltd.