A roll container (roll cage) is a transport container that plays an important role in logistics and storage. It is a mobile mesh container designed to protect goods of various weights, volumes and shapes from damage during transport and handling.

Two basic designs have been used in the development of the various modifications of our roll containers:

- demountable roll pallet;

- nestable roll cage.

Demountable Roll Container

Nestable A Frame Roll Container

An assortment of Nestable A-frame Roll Cages

Nestable Roll Cage FFR.03

| Overall dimensions: 790 x 700 x 1740 mm | |

| Load capacity up to: 550 kg | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised surface |

Nestable Roll Cage FFR.04

| Overall dimensions: 790 x 700 x 1740 mm | |

| Load capacity up to: 550 kg | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised surface |

Nestable Roll Container FFR.05

| Overall dimensions: 790 x 700 x 1740 mm | |

| Load capacity up to: 550 kg | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised surface |

4 Sided Roll Container Nestable FFR.15

| Size: 743 x 868 x 1900 mm | |

| Load capacity: 550kg | |

Shelf load: up to 120kg | |

| Mesh size: 75 x 75 mm | |

| Wheel diameter: 125 mm | |

| Coating: Powder coating/galvanising |

Nestable Roll Cage ARK.01

| Overall dimensions: 680 x 800 x 1805 mm | |

| Load capacity up to: 550 kg | |

| Shelf load: up to 150 kg | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised surface |

Nestable Roll Cage ARK.17

| Overall dimensions: 830 x 700 x 1585 mm | |

| Load capacity up to: 550 kg | |

| Shelf load: up to 150 kg | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised surface |

Nestable Security Roll Cage ARK.22

| Overall dimensions: 830 x 695 x 1825 mm | |

| Load capacity up to: 550 kg | |

| Number of shelves: up to 4 pcs. | |

| Wire-mesh: 50 x 50 mm | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised surface |

Nestable Roll Cage ARK.23

| Overall dimensions: 805 x 685 x 1805 mm | |

| Load capacity up to: 550 kg | |

| Wheel diameter: 125 mm | |

| Coating: Galvanised |

Security Roll Container FFC.07

| Overall dimensions: 1200 x 800 x 2000 mm | |

| Load capacity: 500 kg | |

| Shelf load: 150kg | |

| Wire-mesh: 50 x 50 mm | |

| Wheel diameter: 125 mm | |

| Coating: Powder coated |

Customised order

| Dimensions: on request | |

| Load capacity up to 550 kg | |

| Number of shelves: on request | |

| Mesh size: 50×50/75×75/100×100 mm | |

| Wheel diameter: 125 mm | |

| Coating: Powder paint/galvanic coating |

An assortment of demountable roll containers

Demountable Roll Cages RKM.01, RKM.02, RKM.03

| Base dimensions: 790 x 700 mm | |

| Height of the wall with wheels: RKM.01 = 1835 mm, RKM.02 = 1635 mm, RKM.03 = 1535 mm | |

| Load capacity up to: 550 kg | |

| Shelf load: 150kg | |

| Wheel diameter: 100 mm | |

| Coating: Galvanised or painted surface |

Demountable Roll Cage RKM.04

| Overall dimensions: 790 x 700 x 1835 mm | |

| Load capacity up to: 550 kg | |

| Shelf load: 100kg | |

| Wire-mesh: 75 x 75 mm | |

| Wheel diameter: 100 mm | |

| Coating: Galvanised or painted surface |

Demountable 4-sided Security Roll Cage RKM.06

| Overall dimensions: 860 x 750 x 1800 mm | |

| Load capacity up to: 600 kg | |

| Wire-mesh: 50 x 50 mm | |

| Wheel diameter: 100 mm | |

| Coating: Galvanised or painted surface |

Jumbo roll container RKM.13

| Overall dimensions: 1200 x 790 x 1835 mm | |

| Load capacity: 550 kg | |

| Wheel diameter: 125 mm | |

| Coating: Polymer powder coating |

Jumbo roll pallet RKM.14

| Overall dimensions: 1200 x 790 x 1835 mm | |

| Load capacity: 550 kg | |

| Wheel diameter: 125 mm | |

| Coating: Polymer powder coating |

Jumbo roll cage RKM.15

| Overall dimensions: 1200 x 790 x 1680 mm | |

| Load capacity: 550 kg | |

| Wall mesh: 200 x 150 mm | |

| Base mesh: 50 x 190 mm | |

| Wheel diameter: 125 mm | |

| Coating: Polymer powder coating |

The development of e-commerce and retail has forced companies to look for new, cost-effective solutions to speed up the delivery of goods to their final destination. In the search for this solution, a second condition had to be met, namely the need to eliminate non-environmentally friendly additional packaging materials.

But, in the end, the resulting transport container (which are called: roll cage, roll container, cage trolley, rollcage, cage trolley on wheels, distribution trolley, wheeled cages, supermarket cages ) far exceeded even the wildest expectations.

Our company can offer various customisation options, such as making changes to dimensions, load capacity or adding wheels with brakes to increase safety during transport. An example of such personalisation is the creation of the ARK.17 model for our regular customers, with a height of only 1585 mm for transport in a low-tonnage truck.

Ipris-Profil can also offer production of roll cages for manufacturing businesses with your company’s logo on the identification plate and painting of products in the corporate colours of your brand (according to the RAL catalogue).

In Ipris-Profil you can buy roll containers, both from the presented models, and place an order for the manufacture of roll cages for retail, 3PL and manufacturing businesses on individual specification.

At Ipris-Profil, you can purchase roll containers from the models presented, or order bespoke roll cages for retail, 3PL and manufacturing businesses on individual specification.

The prices shown on the website are indicative. The final price of roll containers depends on the quantity ordered, type of roll cage, type of finish (polymer powder coating or galvanised finish), number and height of walls, number of castors with and without brakes, number of shelves.

However, we would like to draw your attention that Ipris-Profil is the only company in Ukraine, which also has a line of metal cutting and pipe mills and for the manufacture of products we use steel tubes own production, which also positively affects the quality, cost and speed of manufacturing orders.

Order a roll cages

What is a roll container?

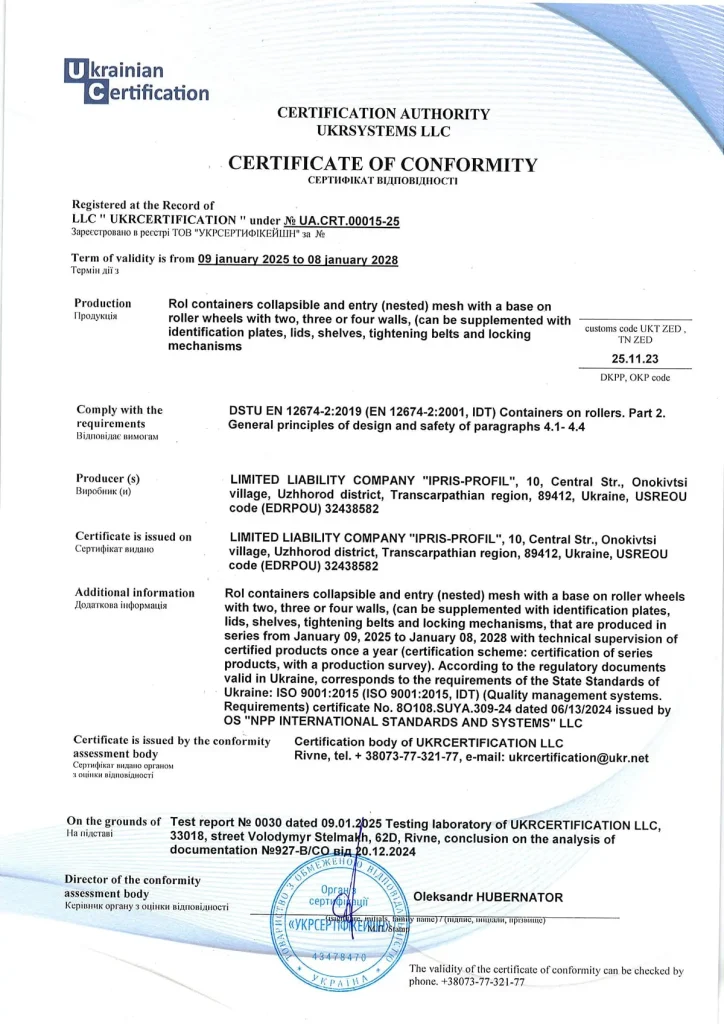

Roll containers are demountable and nestable structures of mesh containers with a base on roller wheels, which can have 2, 3 or 4 walls. They can be supplemented with identification plates, lid, shelves, tie-down straps and locking mechanisms.

How to use a roll cage

These roller delivery trolleys are designed to minimise the need to manually move goods.

The principle of using a roll cage is as follows:

- fully loaded with roll cages with products the vehicle can deliver the goods only to one unloading point or distribute them to several points;

- standard models of mobile containers on wheels and models with increased security (wire mesh security cages with a finer mesh with a lid and lock) for fragile and expensive goods can be transported in one vehicle;

- upon arrival at the end point, employees move the transport container from the vehicle to the sales area and immediately place the goods on the shelves without moving them to storage areas or leaving them in a container;

- return of containers is made in two ways: empty mobile mesh containers are loaded into the car in place of unloaded filled roll containers and the car goes further along the route to the next delivery point, or after unloading the car distributes the remaining roll cages to other points, and on the way back collects empty container trolleys.

Modern technology enables the implementation of tracking and control systems that locate shipments in real time. This approach makes it possible not only to track shipments, but also to optimise routes to increase efficiency.

Advantages of roll containers

- demountable and nestable designs allow transport packaging to be stored in a minimal space when not in use;

- wheeled trolleys are easy to manoeuvre through warehouse aisles, increasing the overall speed and accuracy of the picking process;

- shipping containers are designed to minimise the need for manual handling of goods, reducing the physical strain on workers;

- standardised design ensures compatibility with various vehicles;

- rolling containers can be equipped with adjustable shelves to separate goods by level, three walls and a door to prevent goods from shifting, falling out or being damaged during transport and locking mechanisms to ensure the safety of the transported products;

- roll cages can be adapted to the specific needs of different industries, whether transporting perishables, fragile items or oversized products;

- mesh mobile bins allow for closed-loop systems where these bins are returned after use, reducing waste and providing long-term cost savings.

Our roll containers are widely used in retail, warehousing and logistics in the UK, Germany, France, Norway and other countries to store and transport a variety of products in and around the workplace or between destinations.

Place an order for a batch of roll cages and get favourable manufacturer’s prices!

Roll Container Factory

For any logistics-driven enterprise aiming to enhance supply chain efficiency, selecting a professional roll container factory is a critical decision. Ipris-Profil is a leading manufacturer with a 35,000-square-metre production facility that ensures uncompromising quality control at every stage. As a specialist roll container manufacturer with over twenty years’ experience in the field, we handle everything from manufacturing high-strength steel tubes to advanced galvanising and powder coating processes in-house. Our dedicated R&D department collaborates closely with clients to design custom transport solutions that secure goods, optimise warehouse space and streamline stock movement in the retail and 3PL sectors. By integrating the latest manufacturing technologies, we produce robust, ergonomic roll containers that can withstand the demands of daily industrial use. Selecting a manufacturer with direct production capabilities ensures competitive pricing and the structural integrity required for modern, high-intensity logistics operations.