The automatic control system of the carpet cutting machine is designed for winding, cutting and packaging of various floor coverings.

A special feature of the carpet cutting machine is the possibility of working with several vertical roll carousels using one mobile floor covering cutter. The mobility of the carpet cutting machine is due to the fact that only one unit is needed per row of carpet roll carousels, as it moves on wheels along the row on a guide rail attached to the paternoster structure. This allows better organisation of space and efficient use of technical resources;

The carousel mate cutter is controlled by the operator via a colour touch panel with an intuitive interface that displays the current parameters and status of the IOU. Twelve users with corresponding access levels are pre-set in the control panel of the automated system. In standby mode, it is possible to select the operating mode: “manual control” or “automatic control”;

The floor covering cutting machine allows unwinding, cutting and packaging without removing the roll from the vertikal carousel cystem, providing high efficiency, safety and ease of use, which not only significantly reduces the time spent by sales floor staff, but also speeds up the customer service process.

The material is fed to the length counter via feed rollers driven by a worm gear motor. After measurement, the material is easily rolled up by the take-up rollers and then wrapped in protective stretch film, making the process convenient and fully mechanised.

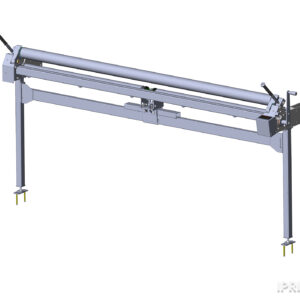

TECHNICAL CHARACTERISTICS OF THE CUTTING MACHINE

| Maximum permissible diameter of the wound bale | 300 mm |

| Permissible bale weight | 200kg |

| Maximum width of the flooring | 4000 mm |

| Roll winding speed | 5 m/min |

| Working level height | 1027.5 mm |

| Length | 5456 mm |

| Width | 722 mm |

| Weight | 505 kg |

| Power supply voltage | 220 V (single-phase), trolley conductor |

Order a carpet cutting machine

One of the key features of an automatic cut-off machine is the use of an electronic angular displacement sensor or encoder to accurately measure the length of the material, with the ability to make adjustments to the length calculation depending on the type and condition of the material being measured.

The carousel mate cutter also has a guide with a knife slot that allows straight and quick cutting of the floor covering with a hand knife. This mechanism makes the cutting process more convenient and economical, without requiring excessive physical effort from the operator.

Safety and reliability: looking after the user

The carousel mate cutter is powered by a movable, sliding, closed trolley current collector, ensuring the highest standards of safety and reliability. This mechanism not only protects the user from possible injury, but also ensures stability throughout the machine’s life.

In conclusion, the carpet and vinyl cutting machine is a progressive solution for those who want to optimise processes and increase efficiency in the trade. Its unique features make it an indispensable tool that combines technological excellence, ease of use and safety.

You have the opportunity to purchase a roll cutting machine for carpet and linoleum directly from our manufacturing plant in Ukraine. Our production facilities are located in Ukraine.