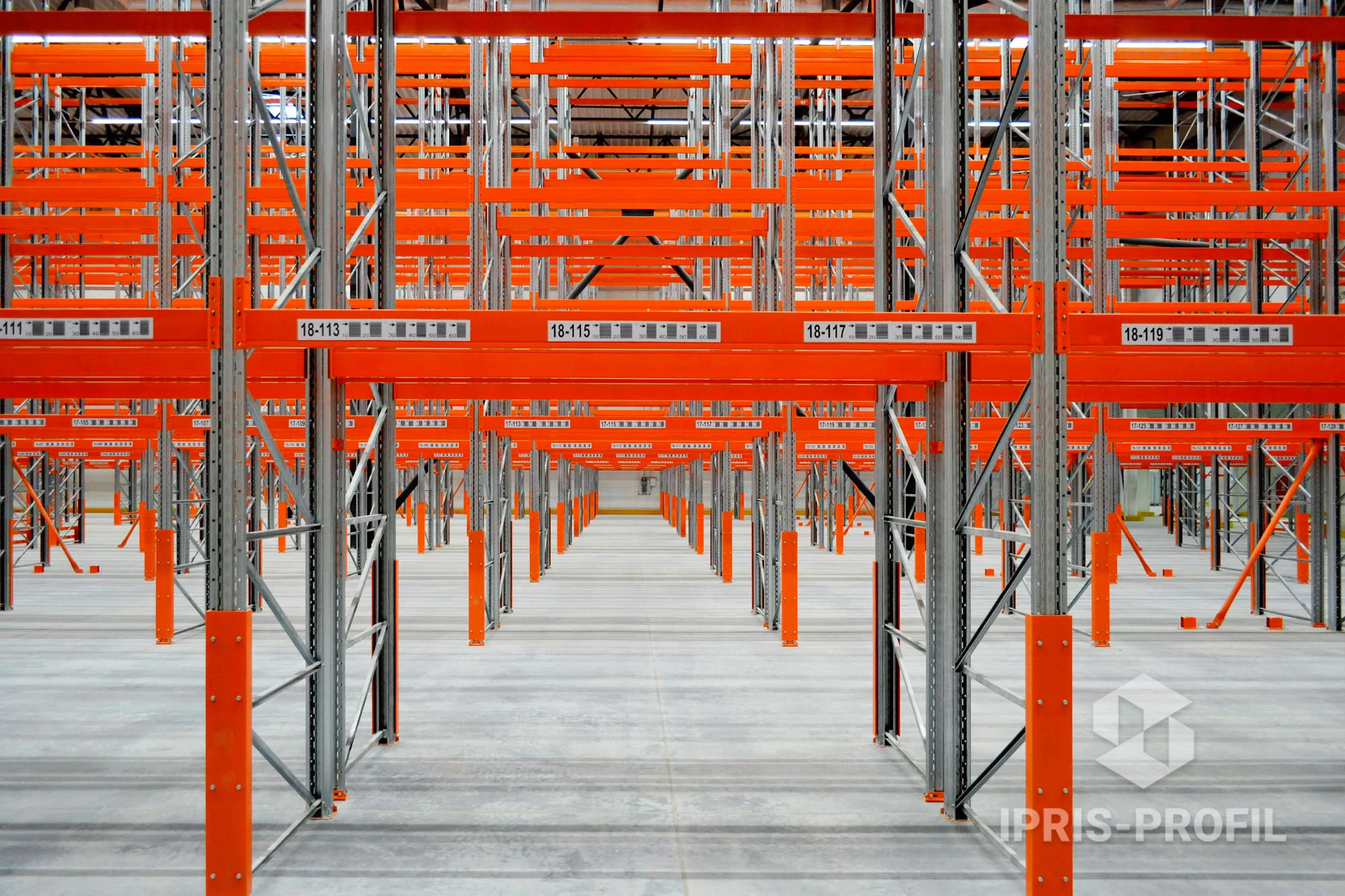

A conventional pallet racking system increases warehouse productivity by allowing goods to be moved quickly to the storage or shipping area. And if you’ve been looking for a highly efficient and cost-effective warehouse design, you’ve found it. These are conventional racking systems.

Characteristics of conventional Ipris-Profil® racks

| Rack height | max 14 m |

| Section load | max 24000 kg |

| Level load | max 6000 kg |

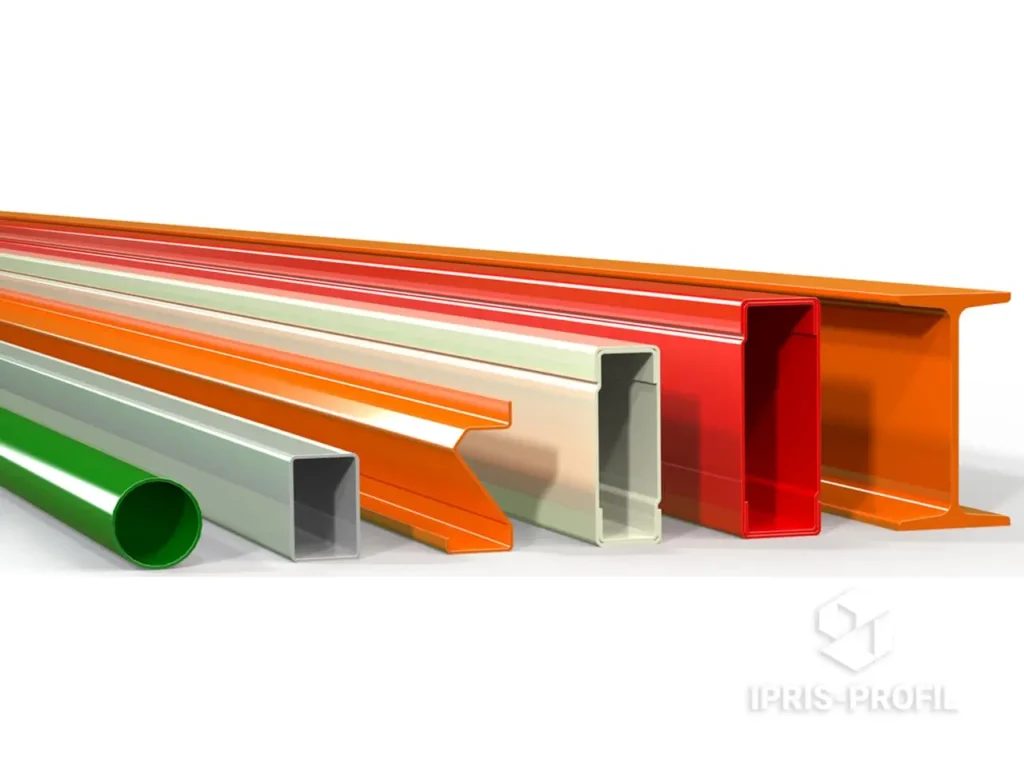

| Enforceability | zinc coating/powder coating |

Simplicity and versatility of design allow to create combined racking systems with shelves on the lower tiers and through corridors in the racks for the passage of loading equipment, which further increases the density of racking systems. You can choose shelves for shelving units here.

In addition, conventional racking systems can be integrated into mezzanine racking.

Another solution to increase the speed of work in the warehouse and efficient use of space is the storage consoles for empty pallets, packing materials and other goods, installed on the end side of conventional shelving.

We can also offer to complete the racks with various accessories, which allows you to organise oversized loads.

Order racks

ADVANTAGES OF CONVENTIONAL PALLET RACKING:

- easy assembly/disassembly and use in daily operation;

- the ability to change the length of the row and the number of tiers without disturbing the structure ensures adaptability to different storage needs;

- possibility of using the lower tiers for shelf storage and manual handling of goods;

- visual control is an effective inventory management model that allows regular monitoring of current stock levels, reducing the risk of stock shortages or surpluses;

- easy access to goods at any level of the rack at any time ensures fast and efficient warehouse operations;

- the ability to create a racking system with bespoke features. Conventional racking can be customised with features such as arbitrary row lengths, rack heights and load capacities to meet the specific needs of the customer.

Construction of conventional pallet racks

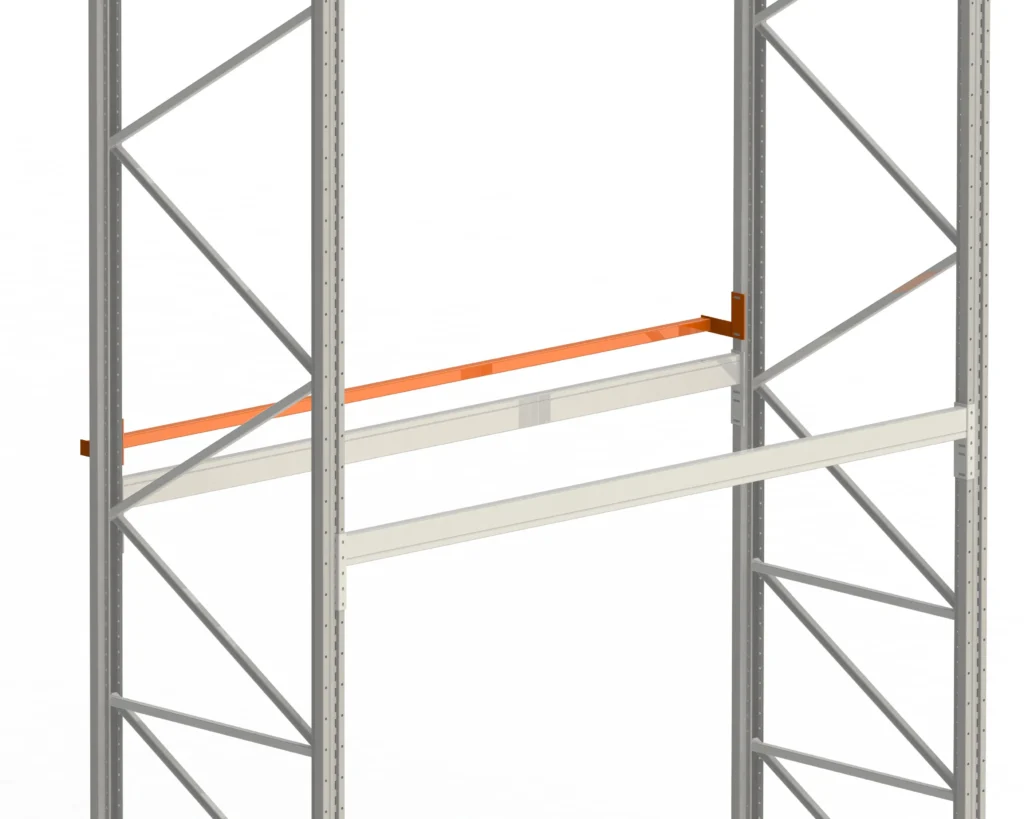

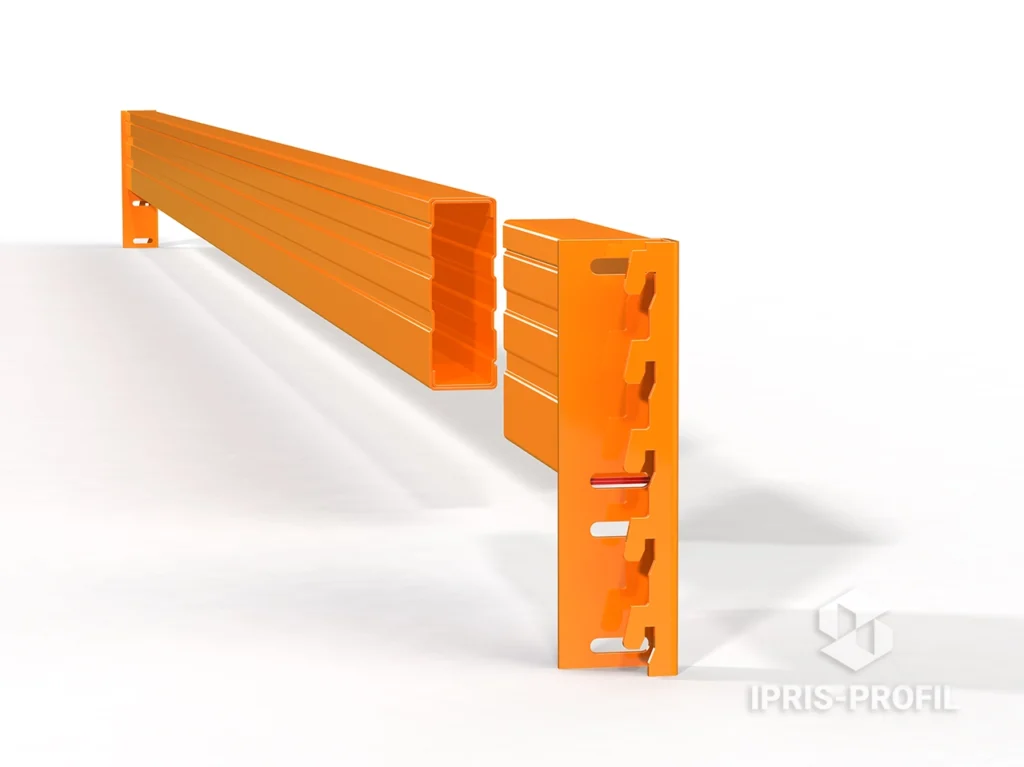

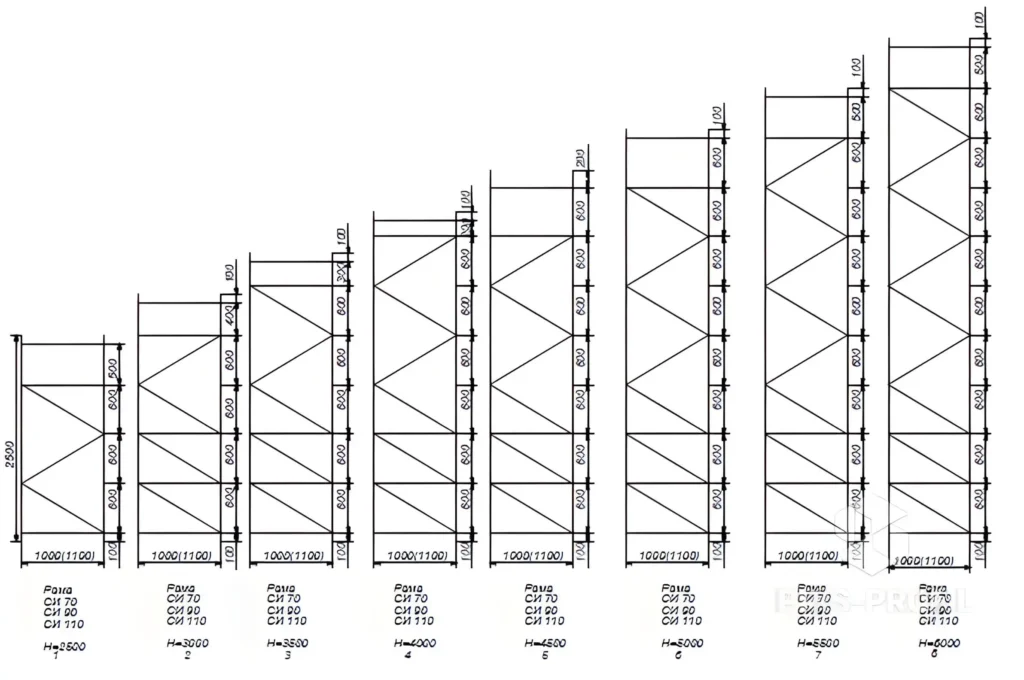

The basic construction of conventional pallet racking is based on frames and rack beams.

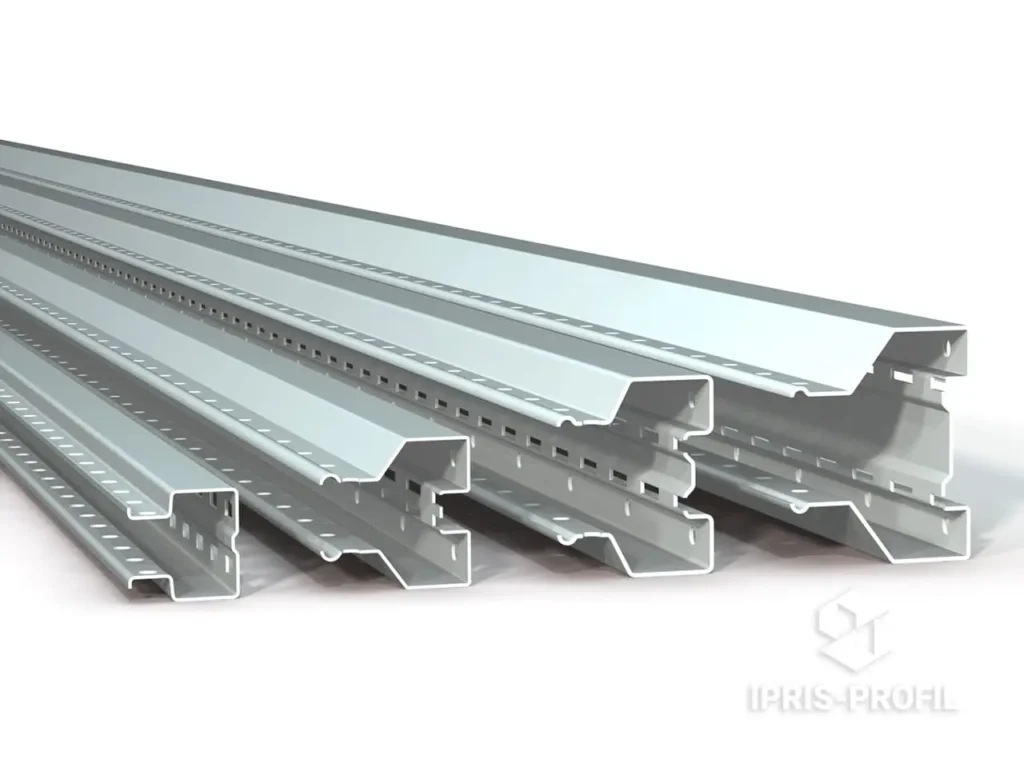

The upright frames are assembled from vertical struts and links.

Rack supports and beams are available in a variety of sizes and section geometries, allowing us to offer our customers efficient storage systems with a margin of safety, but without overpaying. For example, storing foam or mineral wool does not require racking with a maximum load capacity of 24,000kg per section. We therefore make careful calculations and offer a design with a lower metal content.

The beam has hooks on both sides. The design of the hooks prevents the crosshead from accidentally being knocked out of the holes in the post. We also provide additional clips.

The perforations in the posts allow the beams to be repositioned in 50 mm increments.

*We would like to draw your attention to the fact that independent arbitrary rearrangement of the beams without consulting the manufacturer is not allowed.

Safety elements are used to ensure safe handling of the racking structures.

This pallet storage system can be used as a single row mounted against a wall, or create a multi-row configuration for maximum storage density.

The production capacities of Ipris-Profil company allow to fulfil urgent orders for ordinary pallet racks promptly, without affecting the deadlines of scheduled orders.

Our design department will propose the optimal racking layout, taking into account the configuration of the room, efficient use of the available storage space, as well as the separation of the receiving/shipping and order picking areas. As well as an experienced project manager will help to choose the optimal design and will supervise the project at all stages, from the design of the shelving unit to its installation at the site.

Fill out a pre-order for a conventional shelving unit, and a price will be calculated by a project manager based on your specific design requirements.

Buy conventional racking systems at a favourable price from a warehouse systems manufacturer with over 20 years of experience – it’s reliable and cost-effective.