Pallet racks

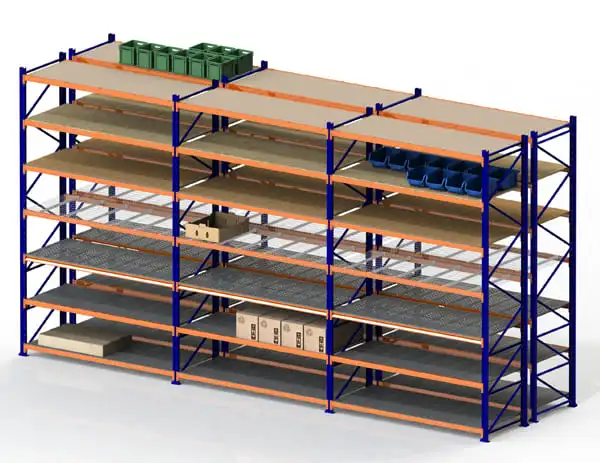

Conventional pallet racking

- for storing the products on EUR and FIN pallets, placing barrels, boxes, oversized cargoes;

- pallets can be installed on both sides of the racking system

Drive-in/drive-through racking

- max pallet loading density;

- for standard and non-standard pallets;

- storage of identical goods or goods with a long shelf life

Warehouse mezzanine

- has up to five tiers of storage;

- access to tiers for employees via stairs;

- delivery of goods to the tiers via the safe loading module;

- storage on pallets and shelves

Mezzanine floors

- free space of the zero level;

- max column pitch – 6 m;

- manufacture of structures with permissible loads from 350 kg/sq.m to 1500 kg/sq.m

Cantilever racks

- single-sided design;

- double-sided design;

- can be integrated into a mezzanine;

- used for storing wood, rolled metal products and other long loads

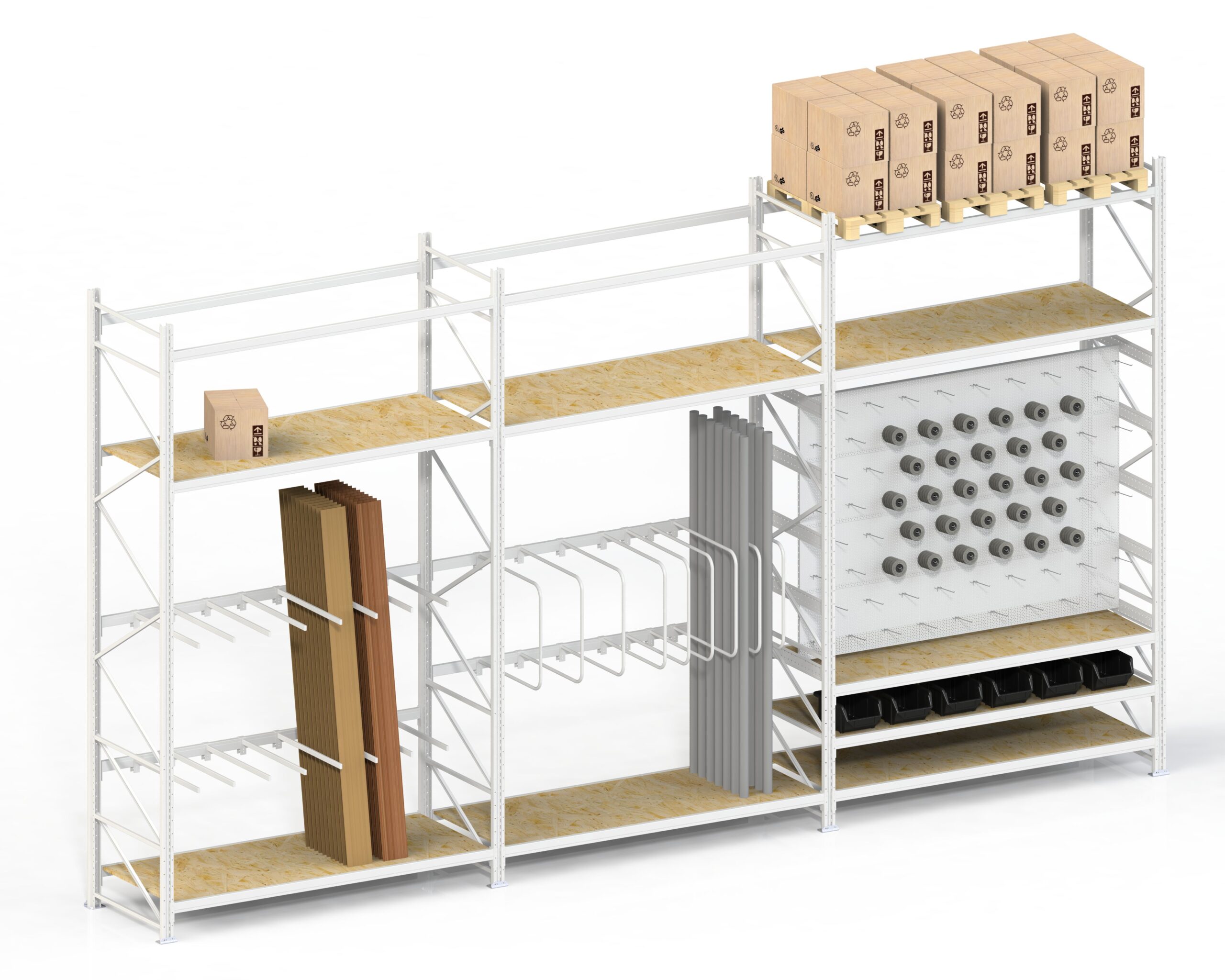

Warehouse shelf racks

- max shelf load 1000 kg;

- max height 12 m;

- free adjustment of the distance between the shelves depending on the dimensions of the load

Archive shelving

- modular design with free space planning;

- twelve shelf sizes;

- arbitrary variation of the distance between shelves;

- galvanised or painted surface

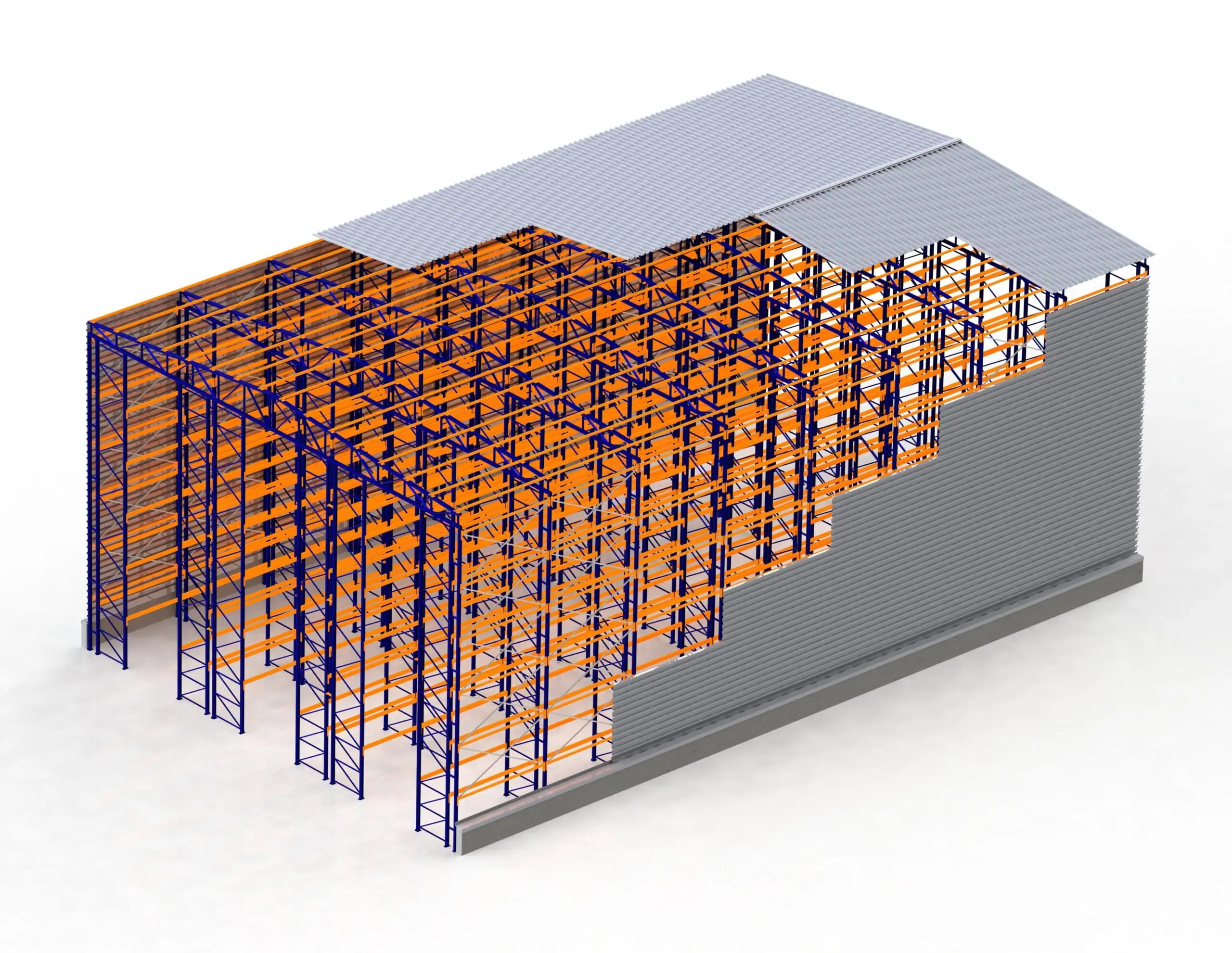

Self-supporting warehouse

- self-supporting construction based on storage racks;

- roofing materials and wall panels are attached to the supporting structure of the racks;

- possibility to increase the storage volume or move the whole structure to another location

Tyre racks

- storage without deformation of tyres;

- different tyre diameters can be stored on the same racking system;

- the racks can be integrated into a mezzanine;

- single and double row construction with different depths and capacities

Retail store equipment for C&C and DIY

- simultaneous placement of goods on the shelves and palletised stock on the upper tiers;

- are in demand in construction shops and Cash&Carry shops;

- special accessories have been developed for favourable product display

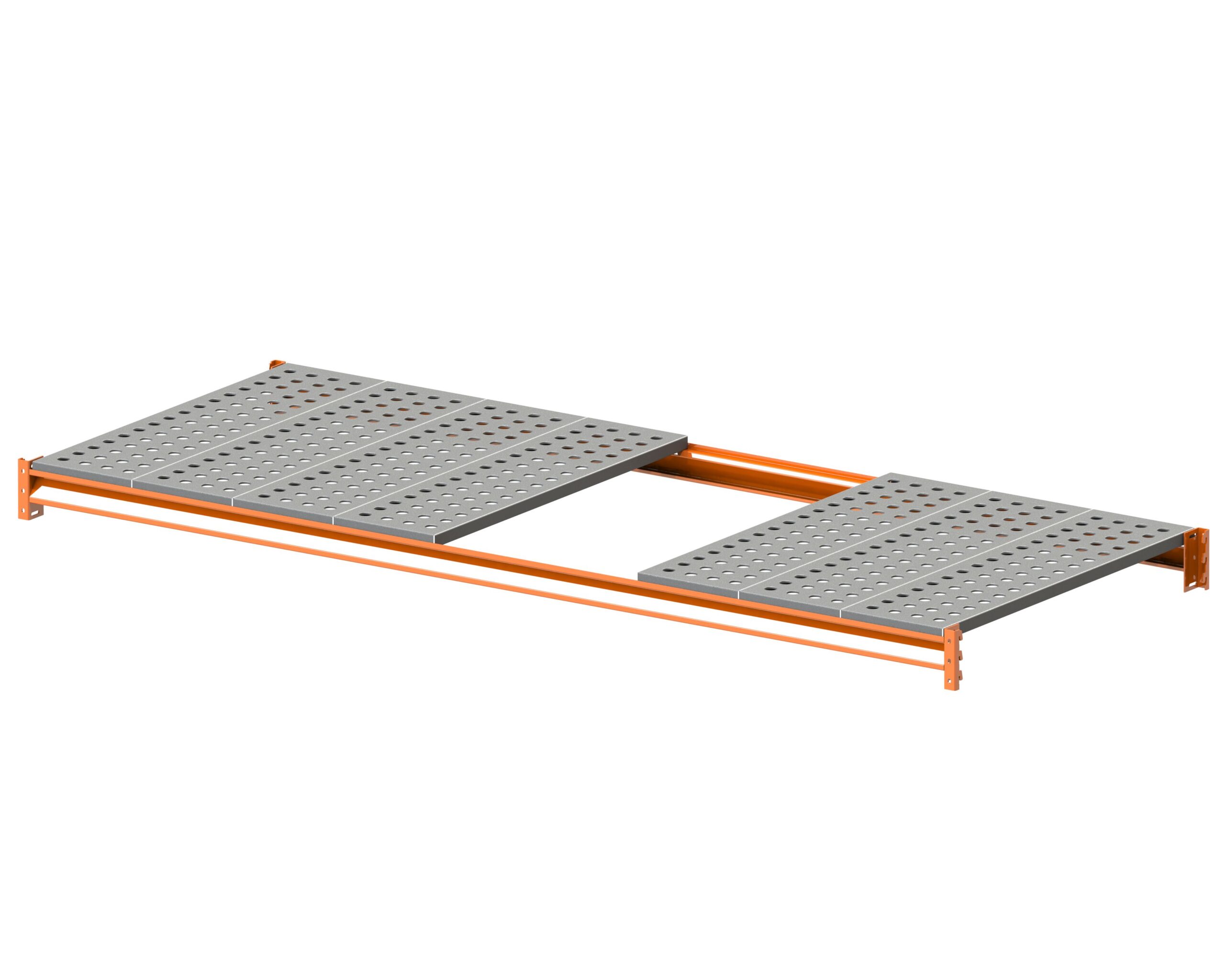

Shelves for racks

- shelving materials: metal, OSB, MDF, chipboard;

- metal shelves with perforated or mesh shelves for warehouses with increased fire hazard;

- overhead and nested construction

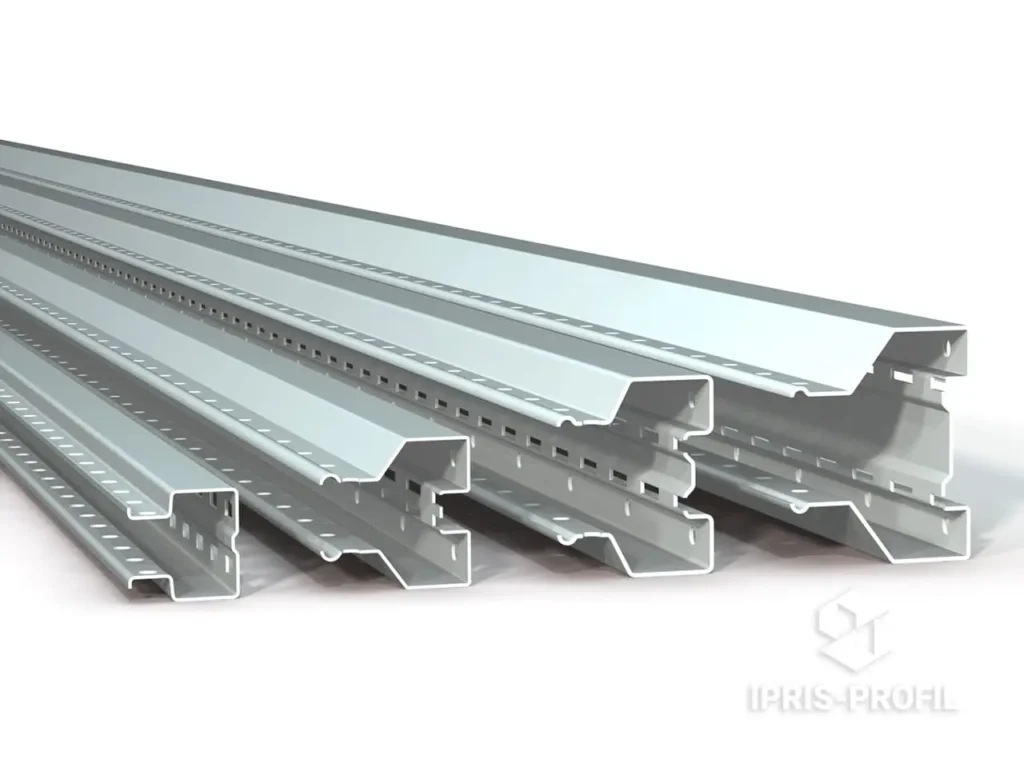

WHICH RACKS DOES IPRIS-PROFIL MANUFACTURE?

Metal racks from the Ukrainian manufacturer are made for:

- warehouse;

- shop;

- archive;

- production enterprises.

The racking structures have both common standard characteristics and are designed and combined according to the customer’s needs.

- According to the principle of cargo storage racking is divided into:

- pallet (cargo on wooden/plastic pallets, in mesh containers, barrels);

- shelf (cargo packed in boxes, crates, plastic containers);

- cantilever (long loads: pipes, metal profiles, wood, skirting boards, sofas in commercial premises, etc.).

- According to the method of cargo placement they are distinguished:

- conventional pallet racking;

- drive-in racks;

- cantilever racking;

- gravity racking;

- warehouse shelving;

- lightweight shelving units;

- racking mezzanine;

- mezzanine floors;

- special racks (for tyres, rolls of fabric or film, sofas, cable reels, etc.)

3. According to the load to be taken:

- light,

- medium load;

- cargo, reinforced, industrial shelving.

4. By method of cargo handling:

- manual;

- with the help of loading equipment.

Industrial shelving is the most demanded type of structures for warehouses, logistics and distribution centers, industrial enterprises used for storing component parts and for storing finished products.

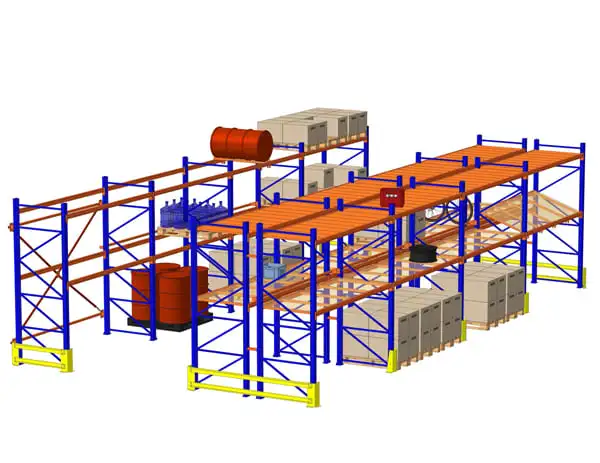

Classic pallet racking with wide aisles for loading equipment

They are served by loading equipment and are the most common and inexpensive design.

The aisles for storage equipment between the racks are about 3 meters and can take up to 40 per cent of the total storage area.

These warehouse pallet racks can be installed:

- single row;

- double rows;

- Double Deep.

Conventional pallet racking with narrow aisles for loading equipment

This is a design of classic metal pallet racking for the warehouse, but the width of the aisles between their rows is 1.5-2.4 metres for the passage of a narrow-aisle stacker.

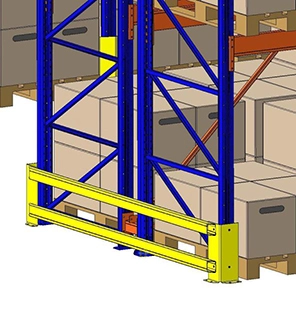

Drive-in racks

Such constructions have a common passage in front of the channels. The technique works in the rack channel, which makes it possible to use 70-80% of the room area.

Depending on the turnover, this storage system is made of two types:

- drive-in. Cargoes, which were installed first, are taken away last;

- drive-through racking system. Cargoes loaded first are taken away first.

Most often they are installed in refrigerated warehouses, when storing the same type of products or goods with unlimited shelf life.

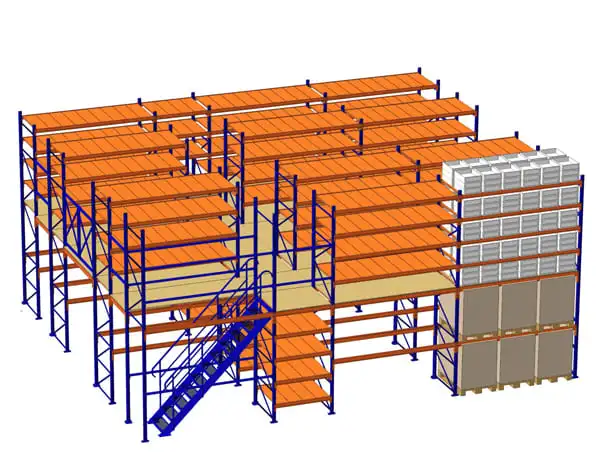

Mezzanine racks

Warehouse mezzanine is an ideal solution for storage or production facilities with high ceilings and manual handling of goods.

The multi-level metal structure can consist of 2-5 floors. The warehouse mezzanine racks contain stairs, handrails and passageways for employee movement.

Easy access to each storage cell increases the speed of cargo handling.

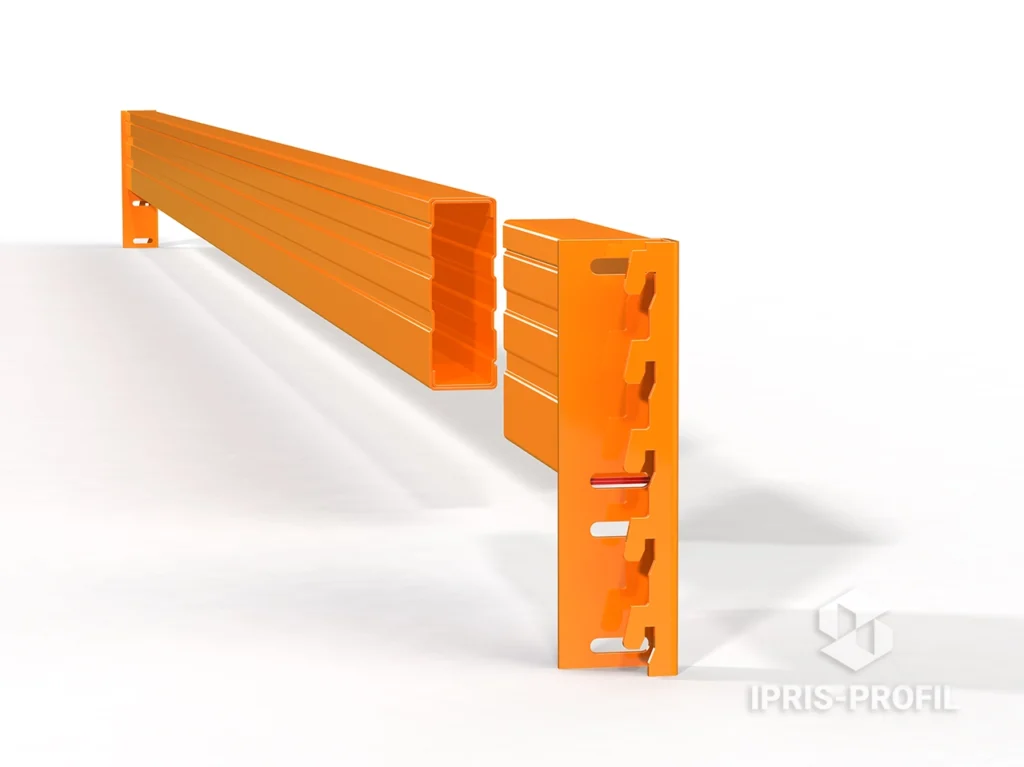

Cantilever racks

Constructions with cantilevers are irreplaceable when storing non-standard large-sized products, such as car components, industrial wood, fabrics, linoleum rolls, lumber, pipes, skirting boards, profiles, etc.

HOW TO CHOOSE METAL SHELVING FOR THE WAREHOUSE DEPENDING ON THE TYPE OF CARGO?

Shelving equipment is selected based on the basic criterion: “Will the loading equipment be involved in the handling of goods in the warehouse?”.

If yes, it is necessary to develop an efficient working scheme for employees, to provide for unloading, loading, packing table, labelling and other areas.

- Pallet racks are designed for pallets/pallets, drums handled by forklift.

- For boxes, piece goods handled by hand – shelf racks.

- For long loads of pipes, wood, metal profiles, etc., cantilever racks are installed in the warehouse.

- In the case when there is no free space, but the room has high ceilings, it is possible to install a warehouse mezzanine. It provides free movement of people or machinery under it or placement of industrial equipment, and the upper tiers serve for shelf storage.

How do you calculate how much racking a warehouse can accommodate?

There are a number of factors to consider when calculating the number of storage racks:

- room height. Ipris-Profil manufactures structures with a maximum frame height of 14 meters. The lower the ceilings, the fewer storage tiers the racking will have, hence the more racking will be required.

- Load characteristics: dimensions of boxes, pallets (EN, FIN or non-standard), height of the load on the pallet.

- the type of loading equipment that will be used. This affects the distance between the racks that must be provided for safe passage.

- The turnover rate of the goods. Industrial enterprises or logistics centers storing the same type of goods or goods with an unlimited shelf life can install padding systems and achieve 70-80% utilization of the usable warehouse volume.

- Fire safety requirements should also be taken into account and the design should allow for freedom of movement for employees, automatic fire extinguishing systems or easy access to areas equipped with fire extinguishers;

- provide for unloading, receiving, sorting, packing and picking areas.

- the size and location of the administrative area for employees.

- distance between walls and storage systems.

Load capacity of warehouse racks manufactured in Ukraine

Metal racks, which Ipris-Profil company produces at its factory, are prefabricated structures and have different load capacity depending on the engineering solution and type of racking:

- conventional pallet racks have a load capacity of up to 24,000kg per section, 6,000kg per tier;

- drive-in racks to 18,000 kg per section, up to 6,000 kg per tier;

- mezzanine racking – up to 4,000kg per storage tier;

- cantilevered racks up to 1,500 kg per tier and up to 6,000 kg per side of racking;

- mezzanine floors up to 2,000 kg per m²;

- warehouse shelf racks up to 4,000 kg per rack side.

- archival metal shelving is designed for light loads and accepts a load per section not exceeding 1,000kg.

How to arrange shelving in the warehouse?

Planning the layout of storage systems is the task of the manufacturer’s design department.

The correct placement of industrial metal shelving in the warehouse is regulated in particular by DSTU EN 15635: 2016 and includes the provision of information to the manufacturer about the turning radius of the handling equipment together with the overall dimensions of the load and the requirements for the width of the working corridor.

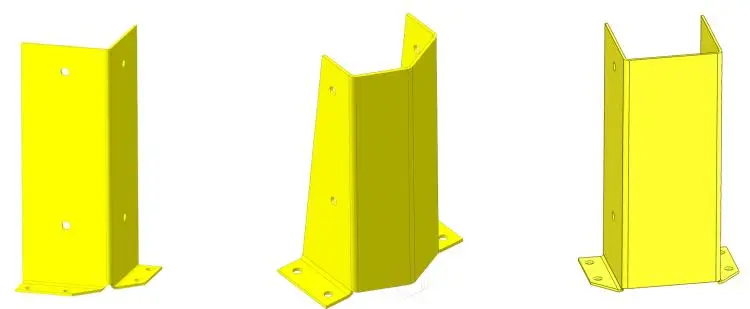

In addition, the number of pallets to be placed on one section and the presence of protection elements for the metal systems against impact from loading equipment (row end protection and frame protection) must be taken into account. When installing paired rows of pallet racks in which the loads are loaded from the front, inter-row spacers – row connectors, and in the case of single rows – stops to prevent the loads from falling out from behind – must be taken into account.

What is the purpose of shelving in a warehouse?

- they ensure orderly, easy and timely access to cargo,

- save money on renting warehouse space because the rented area is smaller;

- they allow for the management of goods flows and prevent oversorting or expiry of goods.

Storage racking dimensions

- For pallet fronts and pallet racking, the maximum rack size is 14 m high.

- For cantilever racks, the size is limited to a maximum height of 6 m.

- Mezzanine on columns is manufactured up to a height of 12 m.

- For shelf racks, the height is limited to three meters.

The row length or slab size of a tiered structure is limited only by the size of the room.

WHERE CAN I BUY RACKS FOR WAREHOUSE FROM THE MANUFACTURER?

In Ukraine you can buy metal racks for warehouses both from the manufacturer Ipris-Profil LLC, which produces warehouse systems in accordance with European standards, which were adopted as national standards of Ukraine in 2015, and from dealers.

To ensure the efficient operation of your company and the safety of life of employees, we carefully monitor the implementation of all points of national and European standards.

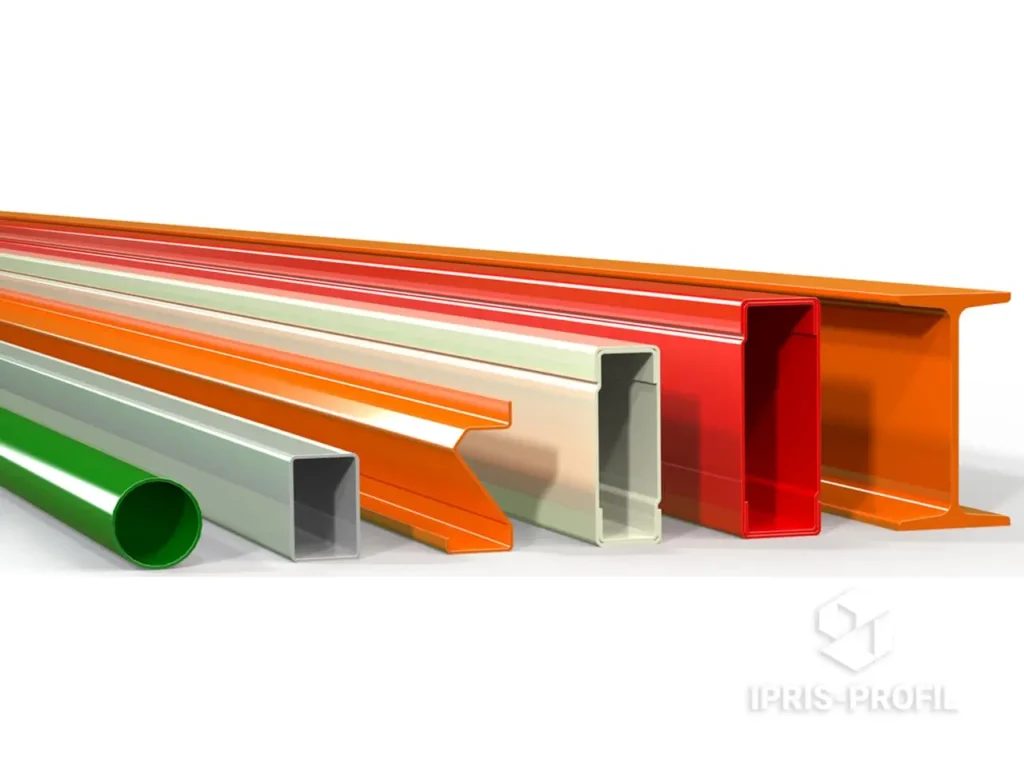

The closed cycle of our production gives you the opportunity to buy quality shelving at a good price because:

- constant availability of metal stock in the warehouse – this means optimal production terms without searching for the necessary steel grade and waiting for delivery;

- own lines of metal cutting, bending, stamping – this is a reasonable price without paying intermediaries for work and delivery;

- our own automatic powder coating line – you choose a color from the RAL catalog and we paint the rack in the color you like;

- free visit of the measuring technician to the warehouse;

- free of charge development of the project with arrangement of storage systems;

- we have experienced staff with in-depth knowledge and understanding of working with different grades of steel to ensure the necessary rigidity, structural reliability and safety of your employees and cargo;

- our design department has developed thousands of projects of varying degrees of complexity over 20 years, which means we can produce customized storage equipment for you.

Buy industrial warehouse racks that will serve you for many years and can be easily disassembled, transported to a new place and mounted again is much more favourable than buying again.

The company “Ipris-Profil”, Kharkiv for 20 years of work among customers throughout Ukraine has established itself as a reliable manufacturer of storage systems of all types.

Information about our capacities and stages of production you can learn more in the section Production.

Buy shelving for warehouse

What does a warehouse rack consist of?

Warehouse racks have a collapsible design, which allows beams to be freely rearranged and the distance between tiers to be changed in 50 mm increments depending on the height of the load.

In addition, shelving systems are equipped with protective elements, supports and limiters.