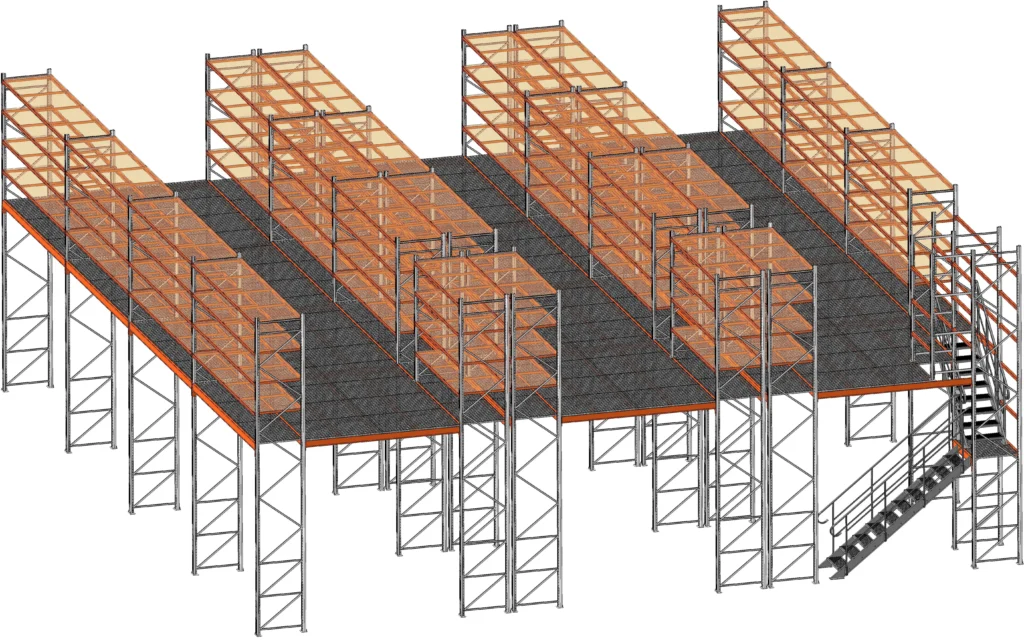

Our company can create fully customised high bay racking designs with the required dimensions, heights, spans, ladders, secure loading modules and much more, from small simple solutions to complex combined multi level platforms.

Ipris-Profil manufactures warehouse mezzanines with the following characteristics:

| Mezzanine height | up to 12,000 mm |

| Section 1 length | from 900 to 3600 mm (in 300 mm increments) |

| Section 1 depth | from 400 to 1500 mm (in 100 mm increments) |

| Load per storage tier | up to 4000 kg |

| Number of floors | 2 to 5 |

| Tiers per floor | 2 to 10 |

| Working corridor width | from 800 to 2700 mm |

| Tier rearrangement step | 50 mm |

| Load per 1 m² floor slab | up to 1500 kg |

Visit the section of our website featuring a variety of accessories and separators for conveniently zoning goods and storing oversized loads on shelving.

WHAT IS A WAREHOUSE MEZZANINE?

A mezzanine in a warehouse is a metal structure, either free-standing or wall-mounted, based on pallet or shelf racks. It forms an additional floor and is installed between the ceiling and the floor to maximise the use of the warehouse’s height.

MEZZANINE APPLICATION

The use of mezzanines is motivated by the expansion of companies that wish to avoid the extra expenses of constructing or renting additional offices or workspaces and recognise the cost-effectiveness of utilising the unused vertical space below the ceiling.

You can identify a number of businesses that have decided to order in Kharkov tiered racks with slabs and use them in:

- In distribution centres. Warehouse mezzanine shelving provides greater storage capacity and is a strategic tool for maintaining smooth operations, improving stock management, and optimizing distribution processes in distribution centers. Maximum efficiency in organizing order picking is achieved by using multipicking trolleys designed and manufactured at the Ipris-Profil factory in Kharkov on the floor shelving.

- In print shops, the mezzanine area is essential. The printing process requires constant control, equipment adjustment, calibration, and other processes that necessitate a constant presence in the shop. However, customer orders, meetings, and documentation must be handled in the office space. Mezzanine-type racks solve this problem without requiring additional investments in purchasing or renting. The multi-storey racking can be designed as a mezzanine on columns to create additional floors under the ceiling without obstructing access to the technological equipment and movement of people and machinery on the lower floor. The finished print run can be stored conveniently on shelf racks on the first or subsequent tiers before delivery to the customer.

- In production facilities, the rack mezzanine has similar characteristics to structures ordered for printing houses. However, the load characteristics are calculated based on the storage of stocks, such as spare parts of industrial equipment, pumps, motors, and finished products manufactured at the enterprise.

- In warehouses with car parts, shipping to retail customers. Buying a mezzanine for this business area, supplemented with ergonomic order picking trolleys, is to create a good warehouse organisation from the outset. For these customers, we suggest supplementing the racking system with separators to organise the storage of small items.

- E-commerce. The presence of a mezzanine enables the systematic organisation of small items by group and nomenclature, facilitating the fast and efficient processing of internet orders.

TYPES OF MEZZANINES

Types of mezzanines that Ipris-Profil has designed and manufactured in Kharkov during its labour activity in Ukraine:

- the storage system consists of two levels, with pallet racking on the lower level and shelf racks on the upper level of the mezzanine.

- a design combining cantilever and pallet racking at the bottom with shelf racks at the top was used.

- mezzanine on the basis of pallet racks on the lower tier and a free area of the intermediate floor for installation of the customer’s equipment;

- for warehouses with high ceilings, mezzanine production was based exclusively on shelf racks with four to five storage levels;

- a combination of a columned mezzanine with shelf storage for a client who wanted to maximise the use of the entire space for storage, but had a need for free movement in part of the building.

After evaluating the client’s goals, objectives, and constraints, the production of mezzanines is customized to meet specific needs for mezzanine solutions and complement the existing facility layout.

MEZZANINE CONSTRUCTION

Mezzanine shelving units consist of:

- posts or columns;

- liaisons;

- traverse;

- strut systems for structural rigidity;

- floor slabs;

- ladders;

- fences;

- loading gates or safety loading modules.

Mezzanine platforms, which are actually the floor of the 2nd and subsequent levels, are usually made of:

- perforated metal decking,

- MDF/OSB boards .

- metal pressed grating followed by hot-dip galvanisation.

Trolleys with loads of up to 1.5 tonnes can travel on the decking.

SAFETY MEASURES FOR THE MEZZANINE

- The safety of employees on the upper floors of the mezzanine in the loading and unloading area is provided by choice:

- with the secure boot module,

- with a pallet gate.

- The stairs are equipped with handrails, a non-skid surface, and an ergonomic angle of inclination.

- The mezzanine is surrounded by a railing to prevent accidents and damage to goods.

Order a warehouse mezzanine

Standards and regulations for mezzanines

As a manufacturer of mezzanines, we strictly comply with life safety regulations. Our multi-storey shelving units are equipped with handrails, ergonomically angled stairs with anti-slip steps, loading gates, or safe loading modules.

When designing mezzanines, the manufacturer for slabs resting on storage equipment takes into account:

- the purpose of using the additional floor, e.g.: for office, rack storage, bridge, etc..;

- maximum load evenly distributed over the floor area not occupied by storage equipment;

- max local loads in the loading and unloading areas or in the selected order processing area;

- max concentrated loads from trolleys and shelving units standing on the floor deck;

- use of anti-slip coating, wear resistance of slab materials;

- fire safety requirements.

The use of load warning labels for use on storage equipment is an important part of ensuring the safe operation and use of the equipment.

What is a mezzanine area?

The mezzanine area is essentially a closed system including ergonomic technological areas:

- unloading zone,

- the zone of goods acceptance by quantity and quality,

- storage area, order picking for dispatch, packing, loading;

These zones are usually connected by aisles and passageways. If the unloading and unloading of goods can be separated by time, these zones can be combined if the mezzanine is small.

When designing a mezzanine storage area perform:

- modelling of the warehouse structure, storage zones and locations, storage racks based on calculations of the required storage capacity, number of cells, etc.

- modelling of aisles and passageways under cargo handling equipment based on calculations of cargo turnover, routes, heights, etc.

Why do you need a mezzanine floor in a warehouse?

- to organise a distribution centre for receiving, storing, completing and shipping goods to the end consumer;

- to increase the storage area by 2-5 times;

- for storing small items;

- to create additional office and administrative space.

HOW IS THE PRICE OF A MEZZANINE CALCULATED?

The price of mezzanine shelving depends on:

- configurations;

- the height of the structure;

- the number of tiers;

- the necessary load-bearing capacity;

- of the slab material;

- in favour of a loading gate or safe loading module;

- the choice of shelf material;

- additional accessories such as separators;

- galvanised or fully painted surface of shelving elements, etc.

Therefore, the price of the rack mezzanine is calculated individually for each project.

To buy a warehouse mezzanine leave an application on our website or any other convenient way.