Mezzanine floors can be installed in a warehouse to multiply the available floor space without taking up additional space on the ground floor. The customised basic steel structure can be easily expanded over time to add a mezzanine floor between the floor and ceiling.

Platform mezzanine is also called: mezzanine systems, intermediate floor, platform on columns, half-floor, mezzanine floor, second tier, mezzanine floor made of steel structures, first floor made of steel structures;

The mezzanine floor is a multi-level structure built into the volume of the main floor of the building, with varying heights at different levels.

A mezzanine floor is designed to optimally utilise the unused space of a building with high ceilings by constructing additional levels on which it can be placed:

- equipment,

- administrative offices,

- shelving for storing stock and finished products.

Characteristics of mezzanine flooring

| Maximum number of storeys | 5 |

| Maximum spacing between columns | 6 x 6 metres |

| Mezzanine floor loading capacity | Slab load capacity: up to 2000 kg per square metre |

| Material of shelves and flooring | metal and wood |

The length and width of the platform can be of any size and is limited only by the perimeter of the room. The configuration of intermediate mezzanine floors can also be of any size, from classic simple shapes, such as square or rectangular, to balcony-type mezzanine.

Ipris-Profil manufactures mezzanine floors according to individual technical specifications with careful calculation of the permissible distributed loads, thus ensuring the safety of your employees and the safety/integrity of stored goods.

For pedestrian decking, you can choose between perforated metal decking, MDF/OSB boards, or pressed metal grating that has been hot-dip galvanized. Industrial steel mezzanine systems are distinguished from other types by their higher loading capacity. Their slabs can support up to 2000 kg per square metre.

You can order in Ukraine the design, production and implementation of mezzanine floors of any configuration with a maximum height of 12 metres. To maximise the use of the building height we can offer production of mezzanine floors with two, three, four tiers above the floor level.

By utilizing the height of a building and implementing mezzanine floors, it is possible to increase the usable area by up to 90%, even in small rooms. As a result, orders for steel mezzanine production are on the rise every year. This is due to the fact that constructing additional space is significantly more expensive than manufacturing a multi-level platform.

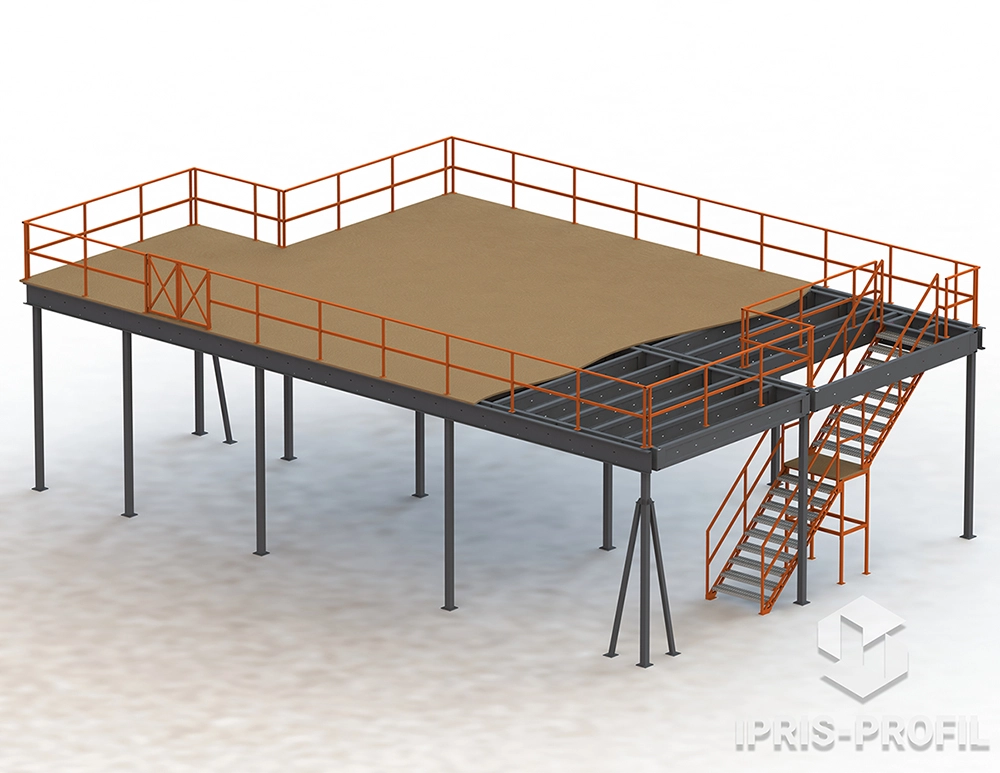

MEZZANINE FLOOR CONSTRUCTION INCLUDES:

- supporting elements – columns. They are made of square tube or I-beams. They have a cross-section from 100 * 100 to 250 * 250 mm;

- load-bearing metal structure that takes the load from the flooring and transfers it to the supports (columns) of the mezzanine is made of C-shaped profiles, Sigma profiles, I-beams. It is a beam structure;

- perimeter fencing with a protective barrier (railing made of square/rectangular pipe, minimum height 1100 mm);

- loading gate or safe loading module (optional);

- classical or spiral staircases manufactured in accordance with the requirements of regulatory documents;

- decking surface material: metal, chipboard, OSB and MDF;

- long-term corrosion protection and attractive appearance of the mezzanine system are achieved by powder coating in any RAL colour on the company’s own automatic line.

The upper tiers are used in a variety of ways:

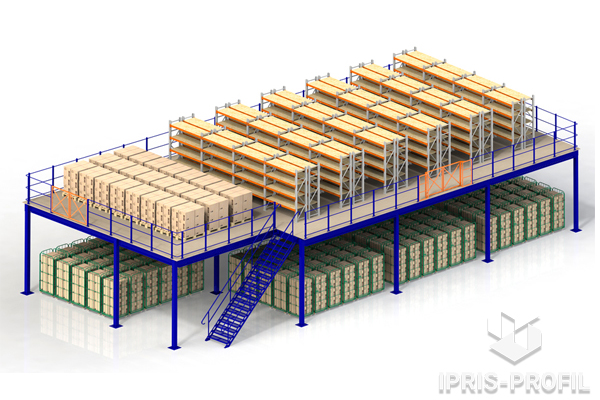

- left empty to store cargo on the “floor”;

- installation of shelving or combination shelving with special accessories for easy product placement;

- they equip administrative and office premises, changing rooms, etc.

Order a mezzanine floor

WHAT IS THE DIFFERENCE BETWEEN A MEZZANINE FLOOR AND A WAREHOUSE MEZZANINE?

- In the case of the storage platform, the walkway is supported on supporting columns, and in the case of mezzanine shelving, it is attached to the shelving frames;

- In the rack mezzanine, the level from the floor to the first floor slab consists of shelving (pallet, cantilever or shelf) and the space underneath the floor platform is free.

ADVANTAGES OF A MULTI-LEVEL MEZZANINE PLATFORM

- increase in space, without the need for capital construction;

- lifting of goods to upper floors by loading equipment through loading gates;

- moving loads on the upper tiers by hydraulic and manual platform trolleys;

- organised nomenclature storage on shelf racks with easy access to each item;

- the mezzanine floor can be extended, modified or moved to another location.

Our factory produces DIY racks and various accessories for them. These additional elements are designed for convenient and orderly storage of various groups of goods, with different parameters of ШхГхххВ. The same accessories we can integrate into a mezzanine floor storage system for you.

The main applications of the mezzanine platform:

- warehouses for spare parts, industrial goods, etc;

- expanding industrial plants;

- supermarkets and construction hypermarkets;

- pharmaceutical industry;

- printing houses, etc.

WHAT THE MEZZANINE FLOOR IS USED FOR

Multilevel structures with columns are used in distribution centres, production plants, printing houses and large warehouses.

Tiers of a platform mezzanine may include:

- floor with administrative offices,

- the picking area,

- finished goods warehouse;

- storage area for goods and components required by the enterprise for the production of its products.

Space under the platform mezzanine is left free for:

- for the installation of production equipment;

- for the storage of oversized cargo;

- for tiered storage of goods in mesh containers, stacking racks or tire pallets;

- for the receiving, sorting, order picking and shipping area;

- for manoeuvring loading equipment;

- for the zoning of the retail space with simultaneous access to the stock on the mezzanine floor platform.

The maximum distance between the columns of the steel structure is 6 metres, which allows:

- Even bulky equipment can be placed underneath and still be easily accessible;

- Leave free space on the floor for moving loading and unloading equipment.

The mezzanine system is a prefabricated steel structure that can be easily dismantled, relocated and reassembled.

If additional storage slabs are created, no building alteration permits will be required.

MANUFACTURERS OF MEZZANINE FLOOR IN UKRAINE

Ipris-Profil®, a mezzanine floor manufacturing company, designs and manufactures warehouse structures of any complexity with delivery to the EU. The staff of our company consists of designers and technologists who have been designing storage systems since the company was founded in 2003, and during these 20 years they have accumulated a huge experience, having developed thousands of projects for both large class A warehouses and small production facilities.

The main criterion for us is the safety of mezzanine floors. It is this criterion that guides us when we issue a new order for production.

Contact us to order a free project design and purchase a mezzanine floor with delivery to the UK, France, Germany, the Netherlands and other countries, as well as the opportunity to order additional mezzanine accessories for growing business needs. Manufacturer’s price.

Ipris-Profil® is your experienced partner in the integration of warehouse technology for distribution and logistics centres and the implementation of large and complex projects. We have the expertise and capabilities you need to achieve the efficient operation of high-tech warehouses.

Our specialists can calculate the exact cost of a mezzanine floor only after full agreement on the project, which must take into account: area, distance between columns, floor covering material, number of tiers, stairs, loading areas, accessories, etc.