The warehouse as a business becomes profitable and begins to bring income to the entrepreneur earlier when the terms of its construction are reduced. At the same time, this type of warehouse allows it to be disassembled and reassembled in a new location, preserving the integrity of the structure.

Professional and responsible construction of warehouse stationary systems throughout Ukraine is carried out by the company Ipris-Profil, founded in Kharkiv in 2003. Manufacturer’s price.

Let us note the existing types of warehouse structures:

- concrete monolithic construction;

- metal construction hangars;

- self-supporting racking warehouses.

FEATURES OF THE CLAD RACK WAREHOUSE

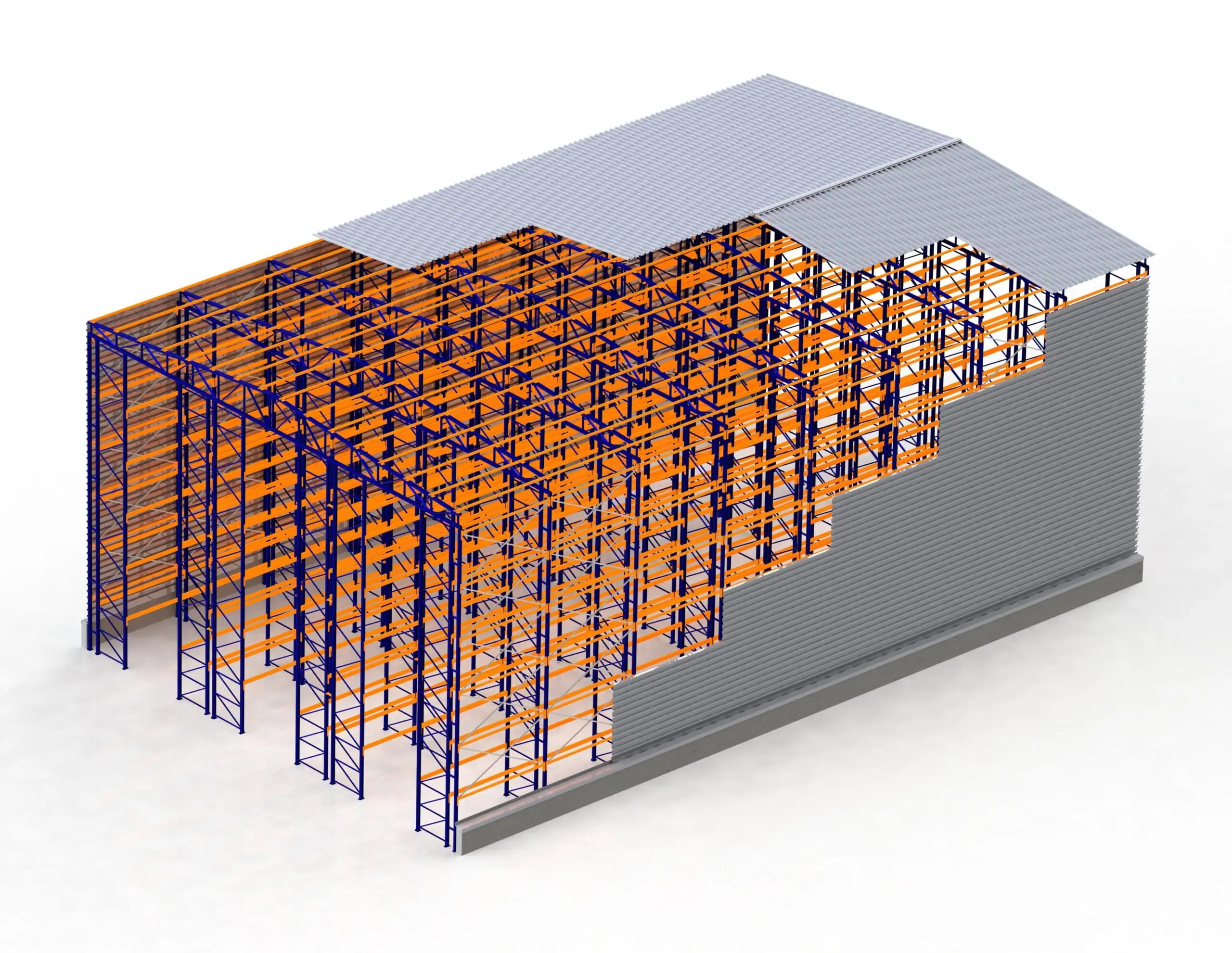

The clad rack warehouse is so named due to the fact that the load-bearing elements of the building are the racks themselves.

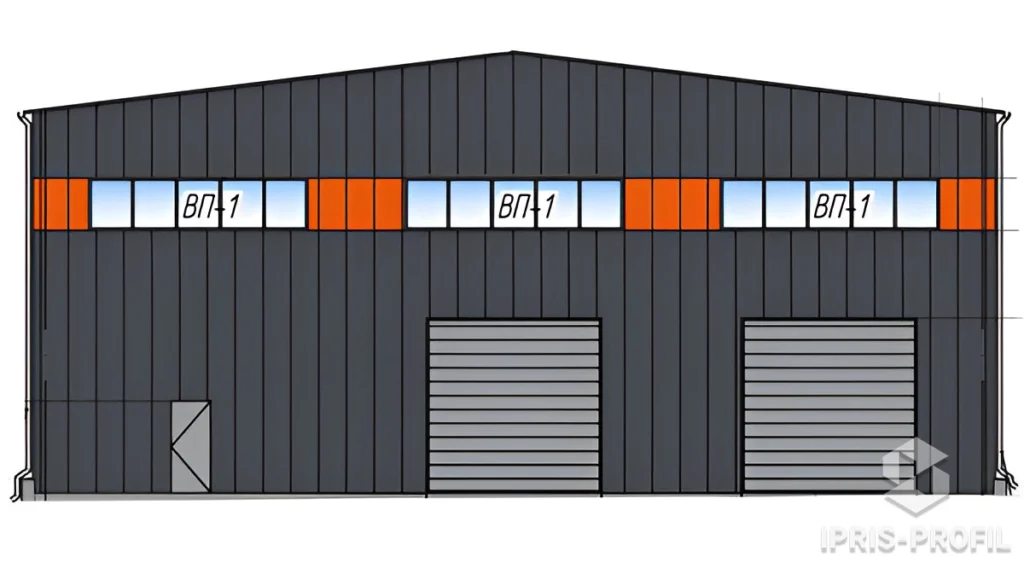

In prefabricated warehouse building, first of all, the racking systems are installed, to which the cladding elements (corrugated board or sandwich panels) are attached, thanks to which the structure acquires a finished look and is ready for operation.

CHARACTERISTICS OF CLAD RACK WAREHOUSES FROM THE MANUFACTURER IPRIS-PROFIL

| SELF-SUPPORTING WAREHOUSE HEIGHT | up to 12,000 mm |

| SECTION LOAD | up to 24,000 kg |

| WAREHOUSE DESIGN ON THE BASIS OF | front, padded and mezzanine shelving units |

| BUILDING AREA | unlimited |

Order a clad rack warehouse

8 ADVANTAGES OF A FAST-MOVING CLAD-RACK WAREHOUSE:

- less time to build a prefabricated warehouse building facility, and therefore your business will start generating profits sooner;

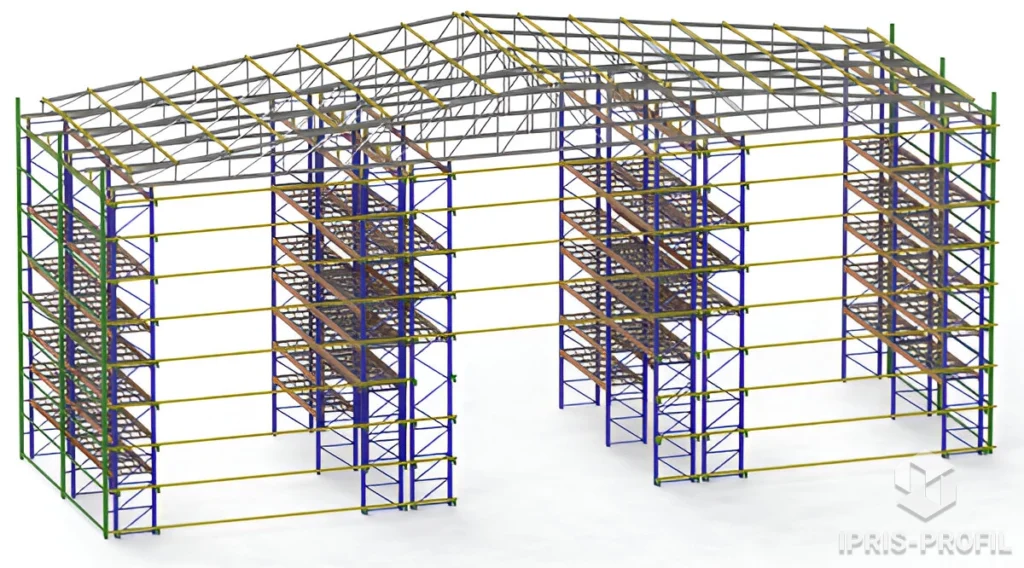

- 100% internal storage utilisation due to the absence of supporting columns;

- possibility of erecting a warehouse up to 12 meters high;

- the cost of a warehouse built on the basis of clad rack warehouses is about 25-35% lower compared to the capital construction of the premises and its subsequent equipping with racking equipment;

- the possibility to expand the warehouse without stopping the internal warehouse processes;

- the possibility to completely dismantle the warehouse structure (using some technologies, even including flooring), transport it to another location (city, region) and mount it;

- the possibility of building your own warehouse, whose technical equipment is adapted to the specificities of the warehousing processes of a particular company;

The company “Ipris-Profil” in Kharkiv produces racks and erects clad rack warehouses. These include:

- cold storage;

- warm warehouses;

- warehouse complexes;

- logistics complexes;

- distribution centers.

What kind of racking can serve as the basis for building a clad-rack warehouse?

We build self-supporting warehouse complexes, taking into account the characteristics of cargo and features of the logistics chain of the future warehouse, so we can offer the construction of both mono-constructions using storage racks of one type, and develop for the client combined racking systems of frontal, cantilever, packed racks.

Or use mezzanine shelving or mezzanine floor to build multi-story self-supporting warehouses.

If you are planning to order a warehouse made of corrugated sheet or metal structures, you have seen different versions of the design, which have common disadvantages – the presence of support columns inside the room or limited height of the structure. Erection of self-supporting warehouses solves these problems.

Stages of construction of clad-rack warehouse by Ipris-Profil company:

- engineer’s visit to the site;

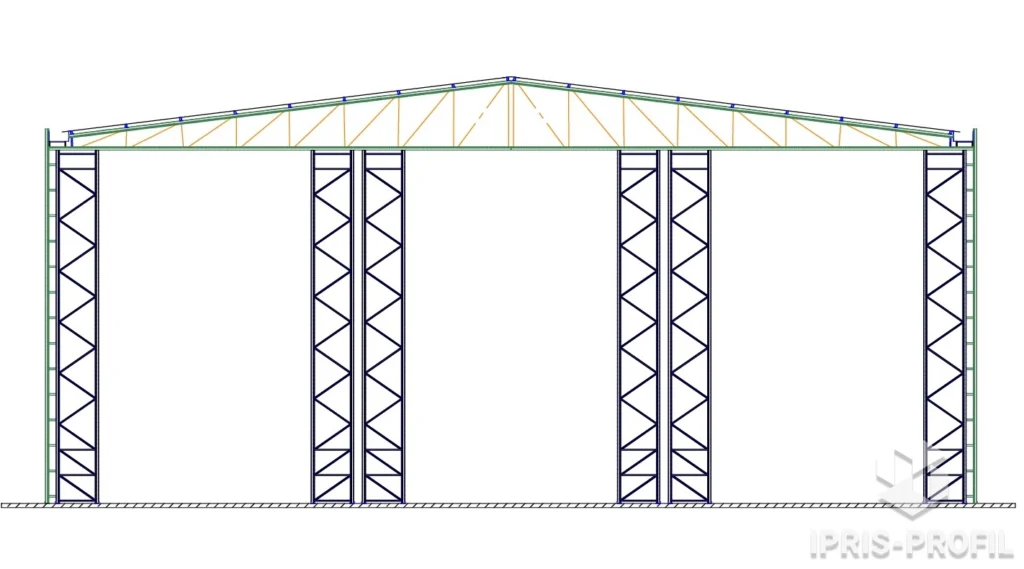

- calculation of the load-bearing capacity of the racks taking into account the weight of the outer skin, snow and wind loads;

- designing the general scheme of the building frame;

- production of racks at the Ipris-Profil plant;

- installation of racks at the customer’s site;

- fixing of wall panels and roofing materials.

Who benefits from the construction of clad rack warehouses?

Customers are increasingly ordering prefabricated warehouse building complexes “for themselves” for the construction of wholesale warehouses of retail chains, logistics complexes or distribution centers, or the construction is carried out for a particular customer through developers in Build-to-suit format with subsequent leasing or sale.

COST OF CONSTRUCTION OF SELF-SUPPORTING WAREHOUSE IN UKRAINE

The final cost of constructing a clad rack warehouse building, logistics complex or distribution center depends directly on:

- area,

- the height of the structure,

- of the materials used,

- fire safety systems,

- technical equipment of the warehouse;

- water supply and sewerage;

- heating and air conditioning;

- power supply and other parameters.

The technical and economic indicators of the project (price) also depend on the class of the warehouse A, B, C or D specified in the design task. It should be noted that warehouses are classified only if all conditions described in Annex A of DBN B.2.2-43:2021 are met. If at least one of the conditions for a class D warehouse is not fulfilled, such a warehouse building is not subject to class classification.

The price of clad rack warehouses based on pallet racking is calculated individually for each project.

To find out the cost of building a warehouse in Ukraine, fill in the feedback form or send a message to our managers.

The price of 5000 UAH per 1 square metre is basic, without delivery from Kharkiv and installation. The final price will be given by a responsible manager after getting acquainted with your technical specifications.

The following factors should be taken into account when ordering a clad rack warehouse from a rack manufacturer:

- Reliability and quality of shelving. You should choose shelving made of high quality materials that meet safety standards and have the appropriate certificates.

- Shelving load capacity. The maximum load capacity of the racking should be considered when selecting the type and model of racking.

- Dimensions and configuration of the metal clad rack warehouse. It is necessary to determine in advance the required number and types of shelving units, as well as the dimensions of the warehouse and its configuration, in order to maximize the efficiency of space utilization.

- The system of storage and selection of goods also affects the choice of racking equipment.

- Operating conditions. The operating conditions of the warehouse (e.g. temperature conditions) must be taken into account.

- Assembly and installation work. Please note that the manufacturer of self-supporting warehouses must ensure that the equipment is professionally assembled and that all necessary installation work is carried out.

Considering all the above factors, you can choose a racking manufacturer that has successful cases and will be able to build a warehouse to organize your warehouse as efficiently as possible.

By ordering the construction of a shelving warehouse based on pallet racking, developing and expanding companies save construction time and get a space that can be expanded later, or dismantled and reassembled in a new location if necessary.