Our knowledge and multi-stage control of production processes according to ISO 9001 quality management system means strong, reliable and safe warehouse structures for your business.

Pallet racks in Kharkov are manufactured in accordance with new rules established in the national standardization of Ukraine:

- DSTU EN 15620:2015 (national standard complies with EN 15620:2008, lDT);

- DSTU EN 15635:2016 (EN 15635:2008, IDT);

- DSTU EN 15635:2016 (EN 15635:2008, IDT);

- DSTU EN 15629:2015 (EN 15629:2008, IDT);

- DSTU EN 15512:2015 (EN 15512:2009, IDT).

WHAT KIND OF RACKS ARE CALLED PALLET RACKS?

Storage, movement and transportation of goods are integral processes of any manufacturing or commercial enterprise. Accordingly, the more goods can accommodate road transport and warehouse, the greater the benefit will be, so the sizes of wooden pallets (pallets) were unified and standardized (EUR-pallet 1200×800 mm, load capacity of 1 ton and FIN-pallet 1200×1000 mm, load capacity of 1.25 tons), and racks for storing pallets began to be called pallet.

Pallet racking, in turn, – is a generalized name for storage structures, meaning the storage of products on pallets that are installed on racking systems.

These systems may be of the following type:

- conventional pallet racking;

- drive-in racking;

- racking mezzanine;

- gravity fed racking;

- push-back pallet racking, etc..

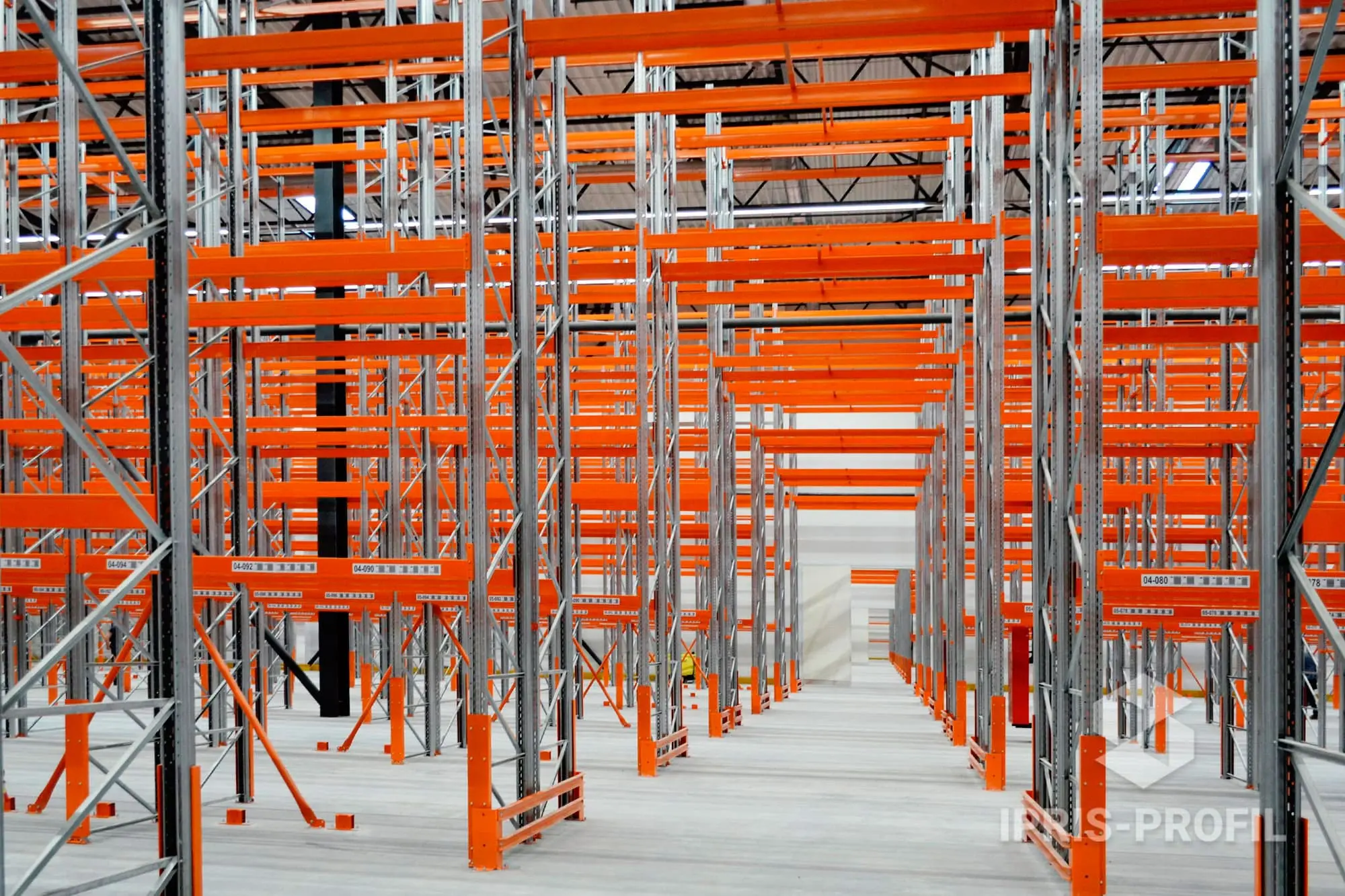

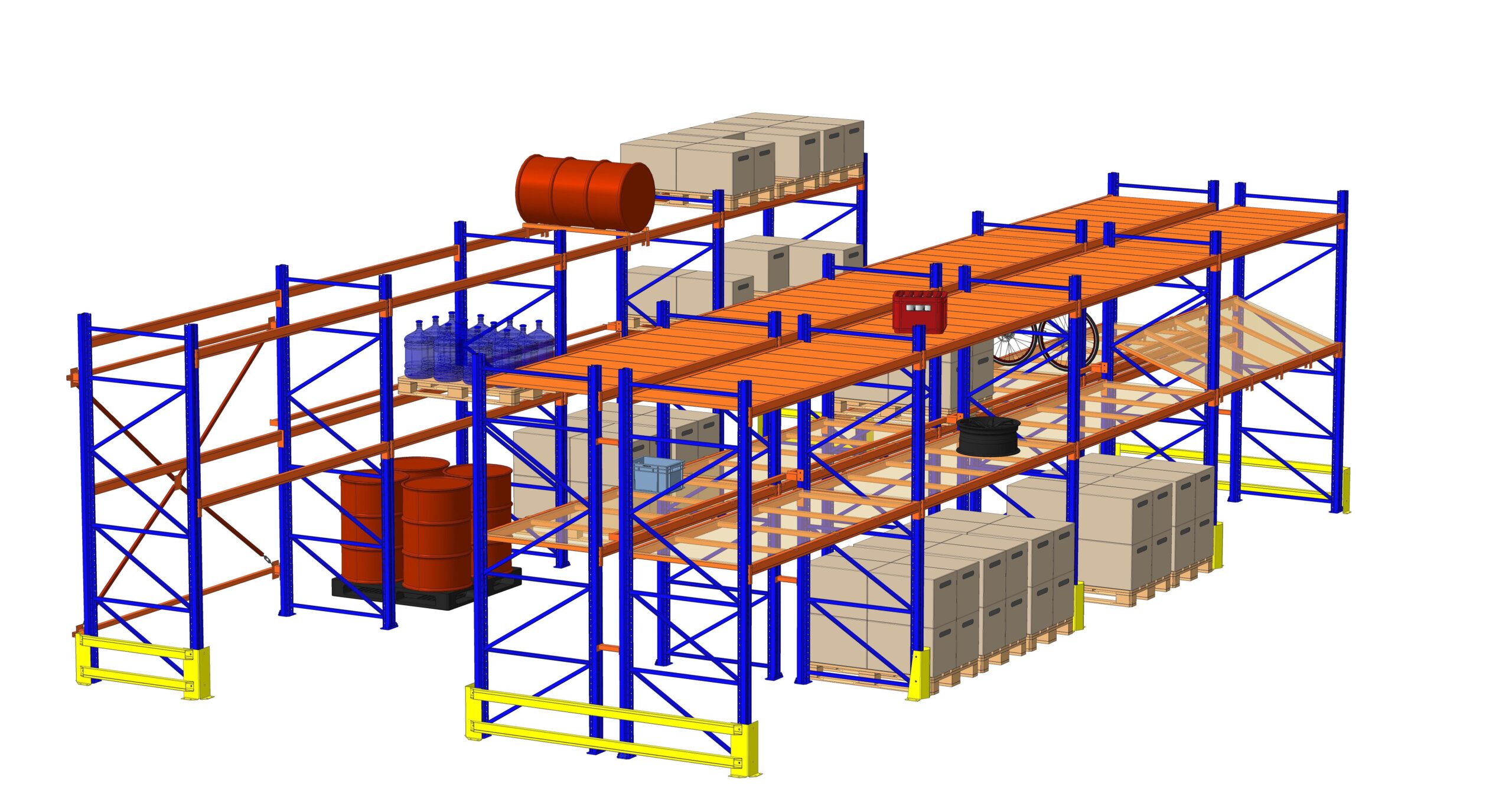

Conventional pallet racking

- for storing the products on EUR and FIN pallets, placing barrels, boxes, oversized cargoes;

- pallets can be installed on both sides of the racking system

Drive-in/drive-through racking

- max pallet loading density;

- for standard and non-standard pallets;

- storage of identical goods or goods with a long shelf life

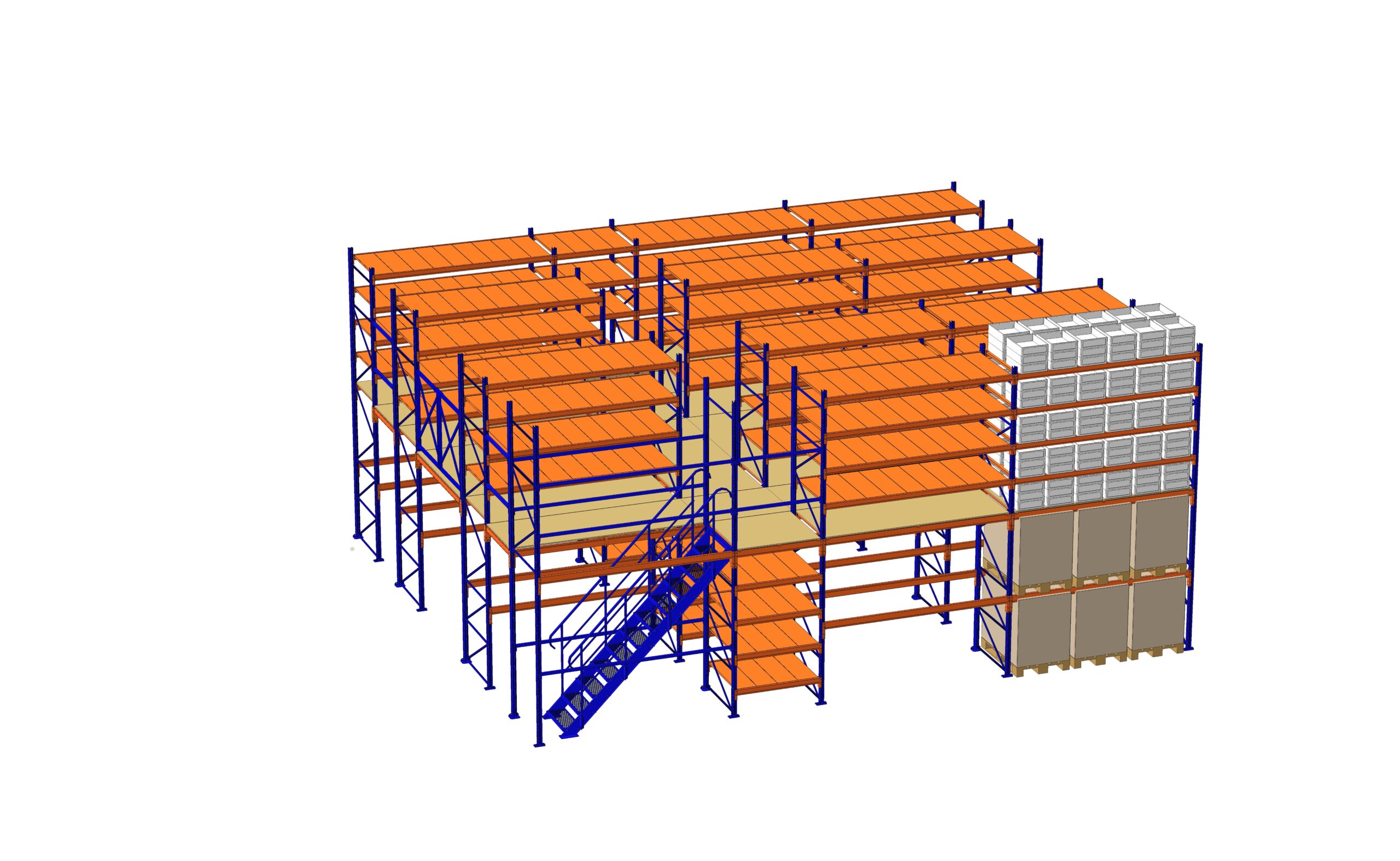

Warehouse mezzanine

- has up to five tiers of storage;

- access to tiers for employees via stairs;

- delivery of goods to the tiers via the safe loading module;

- storage on pallets and shelves

Each of the racking types listed has its own handling characteristics and design differences.

If you’re not sure which type of pallet racking will give you the most efficiency and profitability, we can help you choose from standard systems or design a combined storage system to suit your needs.

PALLET RACKS WITH FRONT LOADING

Ordinary pallet racking is a multilevel storage system designed for the temporary storage of goods on pallets of different types, such as wooden or plastic pallets, rack pallets, and box pallets.

The pallets with cargo are arranged in a single row within the racking sections, and cargo handling is performed from the front side of the structure.

This storage system provides easy access to each cell at any time and facilitates visual stock control.

The advantage of pallet fronts is their expandability and modifiability:

- it is possible to increase the length of the row;

- single (wall shelving), twin rows or double deep (Double Deep) can be ordered;

- you can organize narrow-aisle or wide-aisle storage;

- the lower tiers can be equipped with shelves for storing piece goods.

Please note that each manufacturer of racking structures provides their own tabular data on the pallet rack, which depends on the characteristics of the raw materials used and the availability of specialised metal-rolling equipment.

- This data includes:

- the maximum height of racks,

- maximum load per racking section,

- and maximum load on a pair of crossbeams.

Ipris-Profil factory in Kharkov produces metal pallet racks with front loading that possess the following characteristics:

| Maximum height of pallet racks, mm | Maximum load per tier, kg | Maximum load per rack section, kg | Maximum traversal length, mm |

|---|---|---|---|

| 14000 | 6000 | 24000 | 4800 |

Conventional pallet rack construction

Pallet rack includes:

- one-piece racks, up to 14 m high;

- horizontal and diagonal links;

- traverses with hooks for placing 2, 3 or 4 pallets with cargo;

- elements of protection of racks from impacts by loading equipment.

The racks are an open profile of complex shape with holes 50 mm apart for the installation of crossbars on hooks. This distance between the holes makes it possible to vary the height between tiers more flexibly by simply repositioning the crossbars.

IMPORTANT! Arbitrary, independent changes to the construction of the rack and the weight of the pallets installed will affect the warranty and jeopardise the safety of the warehouse staff and the stored goods.

Why is conventional pallet racking considered versatile?

The Kharkiv pallet racking factory has developed many additional accessories to extend the functionality of the existing design.

For example, we can offer:

- equip the lower tiers with shelves (made of wood, chipboard, OSB, metal, metal with perforations, mesh) to use them for storing piece or unpackaged goods;

- supplement the design with various separators and dividers;

- ensure safe storage of drums and tanks;

- equip the end of the row with consoles for storing empty pallets, etc.

For the storage of bulky goods on the shelves (e.g. door panels or rolls of linoleum), Ipris-Profil can offer the manufacture of metal pallets with the required dimensions and load-bearing capacity.

DRIVE-IN/DRIVE-THROUGH RACKING

Drive-in racking has aisles only in front of the racking channels and can occupy up to 70-80% of the total storage area.

Drive-in pallet racking is economical when a large number of similar goods are stored.

They offer maximum storage density compared to other storage systems.

Loading and unloading operations are carried out directly in the working aisle of the rack.

Drive-int racking design.

This type of pallet racking also contains in its design racks and ties, but instead of longitudinally mounted beams, here are used transversely located beds (guides), on which pallets with cargo are sequentially loaded.

In other words, the working channel of the rack is assembled from the frames, the pallet tiers of which are located on the left and right side.

WAREHOUSE MEZZANINE

This type of racking solves several problems at once:

- Pallet storage;

- Shelf storage;

- Efficient use of the height of the premises by creating additional pedestrian floors;

- Possibility to build administrative and household premises on the upper floors.

The maximum height of the mezzanine is 12 metres.

Maximum number of levels (floors) – 5.

Staircases with handrails are provided for employees’ access to the upper floors, and each floor is equipped with safety railings around the perimeter.

On each floor there are loading doors for lifting pallets with goods by means of loading equipment.

For warehouses with high fire safety requirements, we can offer “spill” perforated galvanised shelving and metal floors made from a set profile with punched holes, or floors made from pressed metal grating with subsequent hot-dip galvanisation.

GRAVITY PALLET RACKS

Gravity racks are similar in design to pad racks, but pallets are not placed on pallet racks, but on angled roller tracks on which the palletized goods are rolled to the unloading area.

These pallet storage systems also make it possible to work with the FIFO system (first in, first out), which is convenient when working with products that have a limited shelf life, or when it is necessary to create a logistical chain of shipping orders with a clear sequence.

Among the advantages of this type of storage systems stand out:

- moving goods by their own weight without the use of machinery;

- storage of large volumes of products on limited space;

- utilization of up to 70% of usable storage space;

- visual control of the load.

PUSH BACK RACKS

A convenient and highly efficient storage system for companies with small storage areas and a limited number of pallets per item.

The method of goods management in Push Back pallet racking is organised according to the LIFO system (last in – first out), i.e. goods are only loaded and unloaded from one side.

Similar to pallet racking, push back can be wall-mounted and is installed as a single unit with no aisles for machinery, providing high storage density.

This storage system allows differentiation of goods by level and access to any level at any time.

The push-back design incorporates inclined rails on which pallet trucks (carriages) move by pushing. The first pallet is placed on the top trolley in the system. The second pallet pushes the first trolley up the rails until the next set of trolleys is available. The rest of the pallets are loaded in the same way, except for the last pallet. It is placed directly on the rails. When the forklift truck removes the first pallet from the shelf, the remaining pallets on the trolleys roll down the inclined rails by gravity to the front edge of the rack.

When loading/unloading in push back, the forklift picks up the pallet from the 1200 mm side, and in the case of gravity pallets, from the 800 mm side.

Ipris-Profil offers the possibility to buy Push Back pallet racks with a maximum number of storage places per level – 6.

WHY IS BUYING PALLET RACKING FROM A UKRAINIAN MANUFACTURER MORE PROFITABLE?

We, at the factory Ipris-Profil in Kharkov, produce 4 sizes of metal profiles for racks: SI-50, SI-70, SI-90, SI-110. Therefore, in cases when it is planned to equip the warehouse with racks with different dimensions and weight of cargoes in the design of warehouse construction racks of the required cross-section are selected, which allows to reduce the metal intensity, due to which the final cost of racks is also reduced. Such variability can only be offered by the manufacturer.

Another option to reduce the price of metal racks for pallet storage with preservation of anti-corrosion properties – manufacture of racks from galvanized steel (standard – powder coating).

The price of a pallet place of storage frontal racks from 500 UAH.

For mezzanines, the price depends on the number of floors, area and number of shelves and/or pallet racks and starts from 800 UAH per 1 square metre of storage area.

For padded pallet racks the price starts from 600 UAH.

Each project is unique and solves its own problems, so the price is calculated individually in each case.

If you are planning to buy pallet racks and have any questions (the price of pallet racks, what type of loading equipment is better, if there is a question of purchase, etc.), you can contact our experts for advice. This includes getting a “second opinion” if you already have a finished project and the cost of manufacturing pallet racking from another manufacturer.

Pallet racking from the manufacturer is a comprehensive approach to equipping your warehouse:

- Site visits to measure and assess the quality of the flooring;

- Identifying the specifics of internal processes to develop an efficient warehouse operation;

- Advising and proposing various technical solutions to maximise the use of warehouse space;

- Project development;

- Manufacture of pallet racking;

- Delivery;

- Installation.

We would be delighted if our knowledge could help your business grow and expand!