These racks are suitable for storing a large quantity of pallets containing a single type of product, such as serialized goods, non-food items, or long-lasting products.

These include:

- appliances;

- canned goods;

- frozen products;

- shoes;

- clothing and textiles;

- carpets, linoleum, carpeting;

- various equipment;

- goods for construction and repair;

- various long cargoes (wood, rolled metal products), etc.

Drive-in racks are installed in manufacturing enterprises under finished products, in logistics complexes, wholesale bases, warehouses of responsible storage, hypermarkets, refrigerated and freezing chambers.

In our company you can buy drive-in racks with different working channel widths:

- for EU pallets (1200×800 mm);

- for FIN pallets (1200×1000 mm);

- for non-standard pallets (max. channel width 2500 mm).

The lack of inter-stack passages and high loading density of drive-in racks enables up to 85% of the room to be used for storage. However, the peculiarities of working with such a storage system limit its application to cargoes consisting of a single item or goods with long, unlimited shelf life.

CHARACTERISTICS OF DRIVE-IN RACKS IPRIS-PROFIL™

| Height of drive-in racks | on Customer’s request (max. 12 m) |

| Section length | at the Customer’s request |

| Section depth | at the Customer’s request |

| Load per storage tier | up to 6,000 kg |

| Section load | up to 18,000 kg |

| Tier rearrangement step | 50 mm |

| Channel width | 1350-2500 mm |

| Coverage type | powder coating, zinc coating |

| Standard colors | blue, orange, yellow |

| Another color | on order |

Order Drive-in racks

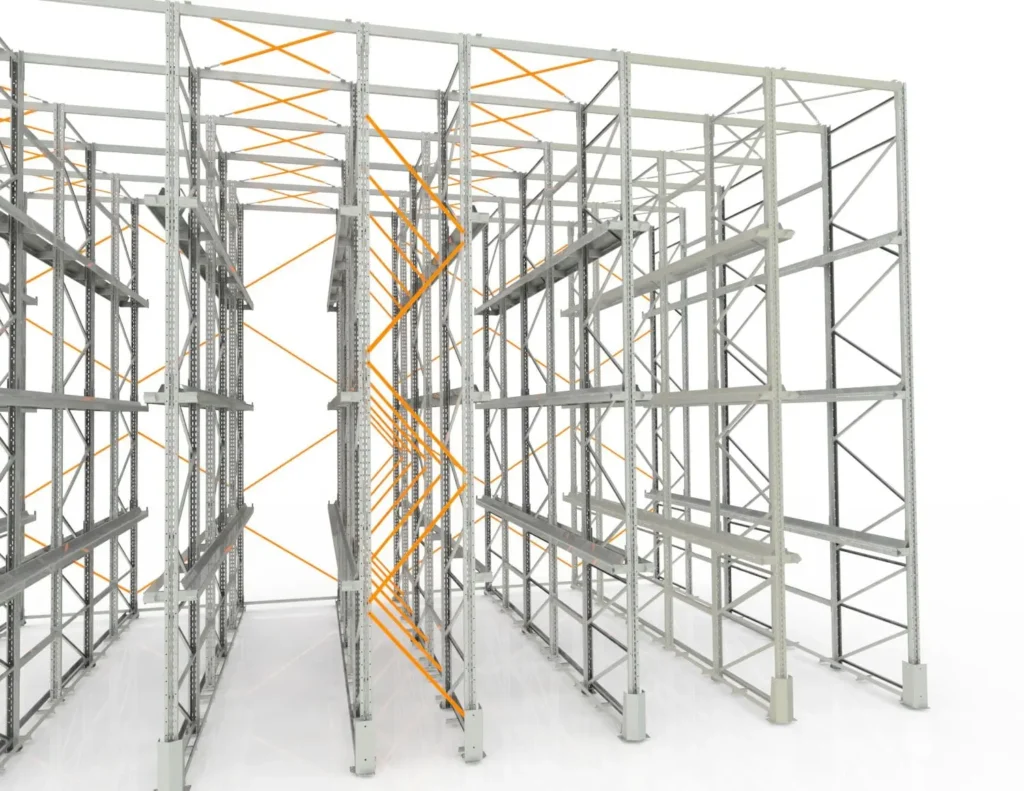

DRIVE-IN RACKING DESIGN

Drive-in racks in a warehouse are installed as a single unit and are a construction of load-bearing frames forming deep corridors (working channels) located side by side, with no driveways for machinery between them. The access aisles to all channels are arranged in two variants:

- only in the front part of the structure (LIFO method);

- in front and on the opposite side (FIFO method).

The pallets are placed deep into the channel on decks that are attached to the supporting frames along the entire length of the channel. Our factory produces fully rolled spacers with a maximum length of 12 m. The width of channels in Ipris-Profil drive-in racks can be standard or non-standard, ranging from 1350-2500 mm.

The rigidity of the structure is provided by diagonal links that connect the frames and racks at the top of the structure.

Since the storage equipment maneuvers inside the structure, increased safety requirements are imposed on the strength and reliability of drive-in racks and we additionally include a trunk channel in the racking system, which ensures the stability of the entire unit.The rigidity of the structure is provided by diagonal links that connect the frames and racks at the top of the structure.

Since the storage equipment maneuvers inside the structure, increased safety requirements are imposed on the strength and reliability of drive-in racks and we additionally include a trunk channel in the racking system, which ensures the stability of the entire unit.

To protect the storage system from collisions and impacts from loading equipment, various bumpers are anchored to the floor without touching the racks.

PECULIARITIES OF WORK WITH DRIVE-IN RACKS

- the forklift truck with pallet drives up to the drive-in rack and takes up a position in the center opposite the working channel;

- the pallet with the load is lifted to a height corresponding to the storage level;

- the loader moves deep into the channel to the unloading point without touching the racks and lowers the load.

- pallets with load in drive in are loaded starting from the top tier. By placing the next pallet under the previous one, the pallets are successively lowered to the bottom tier. Unloading is carried out in reverse order;

- drive-in racks чувствительны к состоянию паллет, поскольку разрушение паллеты на высоте может повлечь неравномерное разрушение системы хранения.

The loading equipment enters the drive-in rack channel to load or unload pallets of goods onto the pallet racks, rather than being in the driveways as with front pallet racking.

The working channels are not intended for through passage of machinery. Only for loading and unloading.

ACCESS TO GOODS LOCATED ON DRIVE-IN RACKS

The inventory management techniques of such warehouse systems are divided into two types (LIFO and FIFO), which affects:

- spatial planning of shelving placement;

- addition of elements for protection of loads from falling out to the design of padded racks;

- planning the layout of maneuvering tracks for storage equipment.

The LIFO principle: first in, last out.

Drive-in racks mounted under loads to be handled by the LIFO method are loaded and unloaded by a forklift truck from one side only. These racks can be installed against the warehouse wall, eliminating the need for a free passage for loading equipment and saving even more space.

The FIFO principle: first in, first out.

The goods in a drive-through racking system are loaded from opposite sides:

- loading is on one side;

- unloading from the opposite side.

For systems operating on this principle, it is necessary to plan for machinery passages on both sides.

All these factors need to be taken into account when designing a drive-through racking system, including warehouse area, pallet size, weight and dimensions of cargo, what volume is planned to be placed, and type of loading equipment.

DRIVE-IN PRODUCTION AND SALES

Customers typically prefer drive-in racks made of galvanized steel over polymer-coated steel due to the lower cost and equivalent anti-corrosion properties. A bright color coating is mandatory for drive-in racks as it helps forklift operators clearly see the required loading level.

The manufacturing of drive-in racks is tailored to the specific needs of the customer, including the weight and dimensions of goods on pallets and the parameters of the warehouse. The cost of drive-in racks for each individual project is calculated based on these parameters. To obtain an exact cost, please fill out the feedback form or contact our experts, who will provide you with an estimate for the production of racks for your project.

If you are uncertain whether drive-in pallet racks are the appropriate solution for your business, please contact our team today. Our team will use their over two decades of experience and expertise to offer you the most suitable solution to save your business time and money by improving space utilization and warehouse efficiency. You may find that drive-in racks are the right solution for your business; however, it may be that a different warehouse system will bring more benefits to your operation.

You will receive the project layout for the drive-in racks along with a quote that includes the exact cost.